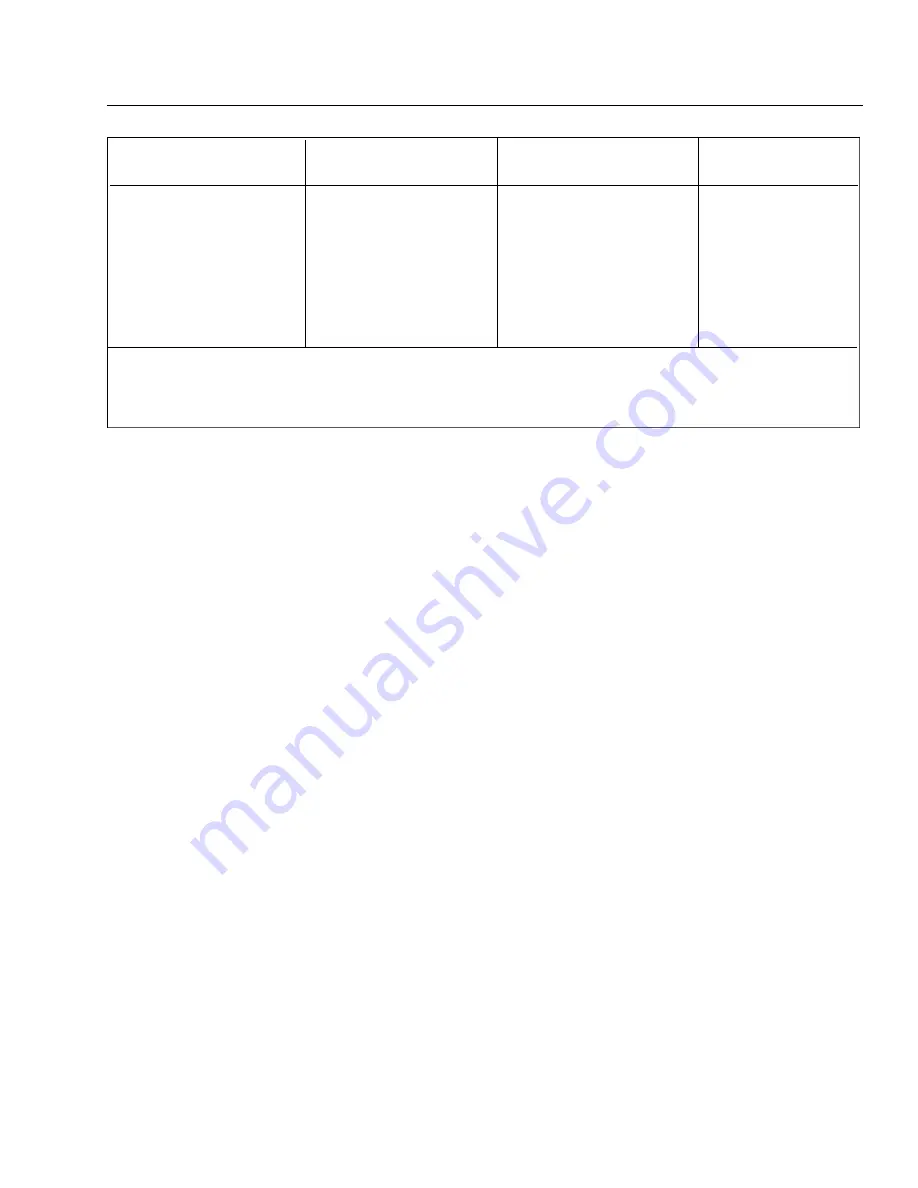

CHART 3503. FILLING PRESSURE FOR CERTAIN AMBIENT TEMPERATURES

2. If a cylinder has less than 5 psi, pressure or has insufficient pressure to produce an audible hissing sound

when the valve is cracked, it should be removed and shall not be refilled.

3. Make sure both the charge valve and recharge "cart" fittings are clean and free of contamination.

— WARNING —

BE CERTAIN THERE IS NO OIL ON THE FITTINGS OR NEAR THE

IMMEDIATE VICINITY.

4. Attach service cart hose to recharge port. Fill the system at a rate not exceeding 200 psig per minute

proceeding as follows:

A.

To obtain the correct filling pressure for the oxygen system at various ambient temperatures, a table is

included for your convenience. The pressures given are not exact, but sufficiently accurate for

practical purposes of working pressures between 1800 and 2400 psig cylinders. The cylinder should be

allowed to cool to a stabilized temperature after filling before checking against the values in Chart

3503.

B.

When using a recharge unit consisting of one supply cylinder, slowly open the valve of the supply unit

and allow the oxygen to transfer.

C.

When using a recharge unit consisting of two or more supply cylinders (cascade storage system), it is

recommended that the following procedure be used:

(1). Before opening any valves~ check the pressure remaining in the airplane's oxygen cylinder. If it is

partly charged, note the pressure indicated on the cylinder gauge. Then open and close each valve on

the cascade storage system and determine which cylinder has the lowest pressure. When found if this

cylinder has a pressure lower than the oxygen cylinder in the aircraft, do not attempt using it for

filling; use the storage cylinder that has a pressure higher than the aircraft's cylinder but lower than the

others.

(2). Open the valve on only the one storage cylinder with the lowest pressure. When the pressure indicated

on the aircraft's oxygen gauge and charging gauge has become equal, close the valve of the storage

cylinder; then go to the storage cylinder with the next higher pressure and repeat the procedure.

(3). If after using the last storage cylinder the aircraft's oxygen system is still not fully charged, a full

storage cylinder should be put in place of a cylinder with the lowest pressure and used in the same

manner.

Ambient Temperature

Filling Pressure

Ambient Temperature

Filling Pressure

0

1650(PSI)

70

1975 (PSI)

10

1700

80

2000

20

1725

90

2050

30

1775

100

2100

40

1825

110

2150

50

1875

120

2200

60

1925

130

2250

NOTE: Filling pressures are for 1850 PSI at 70° F. Table assumes 25° F rise due to heat of compression with

max fill rate.

PA - 4 4 - 1 8 0 / 1 8 0 T

AIRPLANE MAINTENANCE MANUAL

3 5 - 11 - 1 5

Page 35-16

Revised: May 15, 1989

2J24

PIPER AIRCRAFT

Summary of Contents for SEMINOLE PA-44-180

Page 38: ...CHAPTER DIMENSIONS AND AREAS 1B14...

Page 49: ...CHAPTER LIFTING AND SHORING 1C1...

Page 53: ...CHAPTER LEVELING AND WEIGHING 1C5...

Page 58: ...CHAPTER TOWING AND TAXIING 1C10...

Page 62: ...CHAPTER PARKING AND MOORING 1C14...

Page 65: ...CHAPTER REQUIRED PLACARDS 1C17...

Page 70: ...CHAPTER SERVICING 1C22...

Page 98: ...CHAPTER STANDARD PRACTICES AIRFRAME 1E2...

Page 108: ...CHAPTER ENVIRONMENTAL SYSTEM 1E12...

Page 189: ...CHAPTER AUTOFLIGHT 1H21...

Page 192: ...CHAPTER COMMUNICATIONS 1H24...

Page 202: ...CHAPTER ELECTRICAL POWER 1I10...

Page 228: ...CHAPTER EQUIPMENT FURNISHINGS 1J12...

Page 233: ...CHAPTER FIRE PROTECTION 1J17...

Page 238: ...CHAPTER FLIGHT CONTROLS 1J24...

Page 304: ...2A18 CHAPTER FUEL...

Page 325: ...2B17 CHAPTER HYDRAULIC POWER...

Page 357: ...2D1 CHAPTER ICE AND RAIN PROTECTION...

Page 414: ...CHAPTER LANDING GEAR 2F13...

Page 479: ...2I6 CHAPTER LIGHTS...

Page 488: ...2I16 CHAPTER NAVIGATION AND PITOT STATIC...

Page 503: ...2J7 CHAPTER OXYGEN...

Page 524: ...2K6 CHAPTER VACUUM...

Page 535: ...2K19 CHAPTER ELECTRICAL ELECTRONIC PANELS AND MULTIPURPOSE PARTS...

Page 546: ...INTENTIONALLY LEFT BLANK PA 44 180 180T AIRPLANE MAINTENANCE MANUAL 2L6 PIPER AIRCRAFT...

Page 547: ...2L7 CHAPTER STRUCTURES...

Page 582: ...CHAPTER DOORS 3A18...

Page 593: ...CHAPTER STABILIZERS 3B8...

Page 604: ...CHAPTER WINDOWS 3B22...

Page 611: ...CHAPTER WINGS 3C10...

Page 624: ...CHAPTER PROPELLER 3D1...

Page 643: ...CHAPTER POWER PLANT 3D21...

Page 667: ...CHAPTER ENGINE FUEL SYSTEM 3F1...

Page 681: ...CHAPTER IGNITION 3F16...

Page 712: ...CHAPTER ENGINE INDICATING 3H1...

Page 730: ...CHAPTER EXHAUST 3H19...

Page 734: ...CHAPTER OIL 3I1...

Page 743: ...CHAPTER STARTING 3I11...

Page 755: ...CHAPTER TURBINES 3J1...