18

3.6.2 Duct Silencer Installation

A duct-type (in-line) silencer is designed to bolt directly to the blow-

er outlet damper flange. Make certain there is adequate room for

the silencer in the discharge direction. Provide at least 24” (61 cm)

of unobstructed space at the end of the silencer discharge. The air

discharge should be directed into an open area, free of obstructions

and with consideration for personnel safety.

CRUSH HAZARD

The silencer will require a separate support. Do not

use the blower damper or outlet flange to support the

silencer. Apply silicone around the bolt holes of the

connecting flanges, lift the silencer into position and

secure with the hardware provided. Install permanent

supports (customer-supplied) and tighten all hard-

ware before removing the lifting device.

3.6.3 Rotary Air Lock Installation

If a rotary air lock was ordered with the unit, the hopper discharge

will have an adapter already bolted to it. Make certain the bolts

connecting the adapter to the hopper discharge are securely

tightened.

Remove all packing from the rotary air lock and determine its

appropriate position. Keep in mind required clearances, electrical

connections and maintenance. Apply sealant to the flange of the

rotary air lock and to the adapter using 3/8” bolts, washers and

lock washers.

ELECTRICAL SHOCK HAZARD

Disconnect and lockout all power to the rotary

air lock before servicing. All electrical connections

should be made by a qualified electrician according

to all applicable codes. Refer to the nameplate and/

or documentation for voltage, amperage, cycle and

proper wiring. Refer to rotary air lock vendor docu-

mentation attached with air lock device.

MOVING PARTS

There are moving parts on the rotary air lock. Do not

allow any object to be placed in or near the rotary air

lock during operation. Verify rotary air lock rotation

matches rotation arrows affixed to assembly.

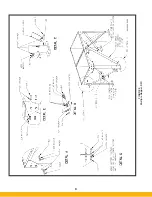

3.6.4 Abrasive Inlet Installation

The abrasive inlet is designed to use the front access panel(s) of

the SFC Series modules as the inlet area to the unit. There are two

styles available – a single or dual module abrasive inlet. Each is

designed to fit over the appropriate number of front access panels

to serve as a single inlet point for one or two modules (refer to

Figure 12).

Remove the front access panel(s) located above the QuickSeal

filter access doors. Save the hardware. The hardware will be used

to attach the abrasive inlet. Remove any remaining gasket material

from around the perimeter of the opening.

Apply a 1/4” (6 mm) bead of sealant around the perimeter of

the access opening in a “figure 8” pattern around the bolt holes.

Align the hole pattern on the abrasive inlet with the hole pat-

tern on the unit and bolt together using the hardware removed

earlier. Fasten the inlet ducting securely to the abrasive inlet

assembly.

The bottom plate of the abrasive inlet will serve as an inspec-

tion plate. If access to the abrasive inlet is required, remove

and clean out the bottom plate of the inlet prior to servicing. Do

not damage the ribbon of gasket and reuse after cleaning the

gasket surfaces.

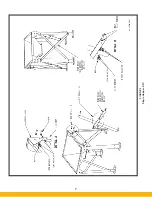

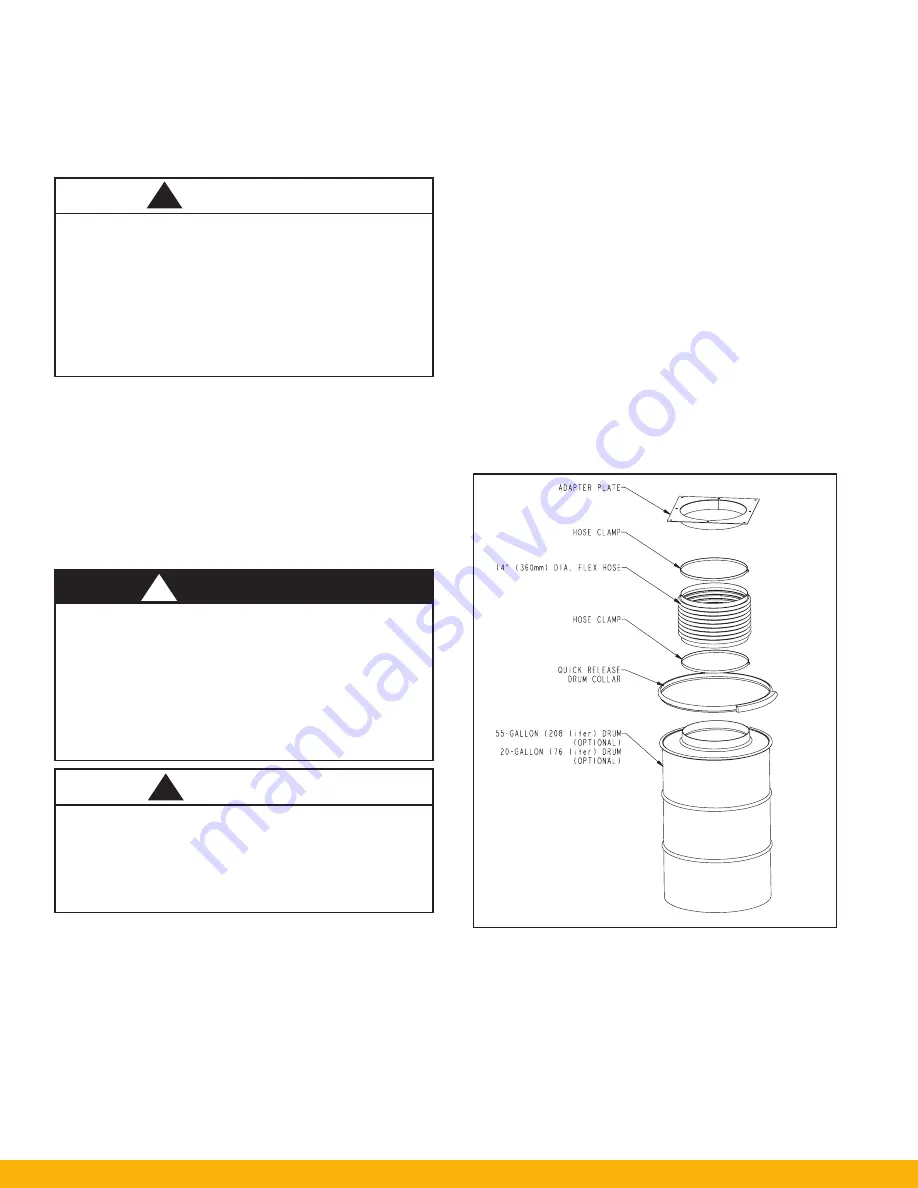

3.6.5 Drum Lid Installation

The drum lid package is an optional accessory for the SFC

Series dust collectors. Refer to Figure 13.

Remove the drum lid package from it shipping carton. Place the

drum lid on the 55-gallon (208 liter) drum or the 20-gallon (76

liter) drum. Slide the 14” (360mm) diameter hose over the drum

lid and secure with hose clamp. Position the drum assembly

under the unit, slide the hose up onto the 14” adapter collar on

the hopper and secure it with a clamp.

!

D A N G E R

44-10046-0001

FIGURE 13

Drum Lid Installation

!

WARNING

!

WARNING

Summary of Contents for SFC

Page 1: ...Downward Flow Cartridge Dust Collector Owner s Manual Model SFC...

Page 7: ...v Page intentionally left blank...

Page 11: ...4 FIGURE 2 SFC Typical SINGLE UNIT Installation Diagram PARKER PARKER 44 10335 0001...

Page 12: ...5 FIGURE 3 Recommended Unit Clearances 44 10337 0001...

Page 14: ...7 FIGURE 4 Single Hopper SFC 44 10309 0001...

Page 15: ...8 FIGURE 5 Multiple Hopper SFC 44 10309 0002...

Page 16: ...9 FIGURE 6 Multiple Hopper SFC 44 10309 0003...

Page 17: ...10 FIGURE 7 Multiple Modules SFC 44 10310 0001...

Page 19: ...12 FIGURE 8 SFC Pressure Gauge Installation 44 10333 0001 Rev A...

Page 20: ...13 FIGURE 9 Solenoid Wiring to Pulse Controls for 2 3 4 and 5 Tier Units...

Page 21: ...14 FIGURE 10 Pneumatic Valve Assembly 44 10332 0001...

Page 24: ...17 FIGURE 12 Abrasive Inlet Installation 44 10338 0001...

Page 27: ...20 FIGURE 16 EDAP Interconnection FIGURE 15 EDAP Installation 48 10007...

Page 30: ...23 FIGURE 17 SFC Series Door Filter Installation 44 10329 0001...

Page 37: ...30 7 Illustrated Parts FIGURE 21 SFC Series 44 10330 0001 FIGURE 22 SFC Series Explosion Vents...