21

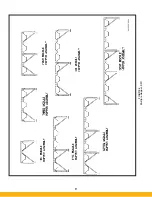

3.6.8 Explosion Vent installation

3.6.8.1 Introduction

Your Parker Dust-Hog® supplied with an explosion vent is

designed to minimize structural damage in the event of an explo-

sion. It does not prevent explosions!

The responsible user should:

1. Take every possible precaution to prevent a fire or explosion

from occurring

2. Consult with their insurance carrier or local authorities regarding

the hazardous nature of dust produced by them.

3. Consult and comply with national and local codes or bulletins

when determining location and operation of the dust collector.

4. Do not exceed negative operating pressure of the unit.

5. Do not exceed operating temperature of the dust collector (not

to exceed 180°F (82°C)).

3.6.8.2 Operating & Precautions

1. Install unit with the explosion vent directed away from occu-

pied areas.

2. When the explosion vent is properly installed, the rating tag

and caution stickers should be in plain sight for all to see. If

the explosion vent is installed incorrectly, damage could occur

to the explosion vent and to the operator or plant equipment.

3. Ductwork added to the explosion vent flange may create a

secondary hazard. User must comply with NFPA standard 68,

and/or other codes that apply.

4. Do not place hands or any other objects in vent opening.

Serious injury or damage to plant equipment could occur.

5. If any leakage occurs, shut down unit and contact Parker

immediately.

6. Never inspect explosion vent(s) with unit running.

7. Only use explosion vent supplied by Parker.

8. Any vent installed, which has been provided by someone other

than Parker will void all warranties on the dust-collector.

In case of explosion, contact Parker immediately.

Do not operate or rearm the collector with another

explosion vent without contacting Parker first.

Serious injury could occur.

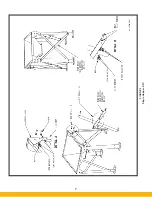

3.6.8.3 Unit Set-Up

The normal shipping routine for an assembled SFC unit is with an

enclosed box truck. This type of truck will not be able to trans-

port an assembled 4-high unit due to height restrictions within

the vehicle. When shipping this unit, it will be necessary to ship

the top panel and explosion vent separately. This will require the

customer to assemble this to the unit on site. Refer to Figure 14

for assembly details.

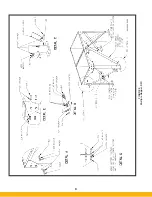

3.6.9 Extended Dirty Air Plenum (EDAP) For 5 High SFC Unit

The normal shipping routine for an assembled SFC unit is with an

enclosed box truck. This type of truck will not be able to transport

an assembled 5-high unit due to height restrictions within the

vehicle. When shipping this unit, it will be necessary to ship the

EDAP separately. This will require the customer to assemble this

to the unit on site. Refer to Figures 15 & 16 for assembly details.

3.6.10 Sprinkler Coupler

CAUTION: Water sprinkler systems can deliver high volumes of

water when activated and in turn can fill up the dust collector,

collect in particulate collection drums and saturate filter car-

tridges. Large amounts of water inside the dust collector can

and will add excess weight to the structure including stress to

the support and extension legs resulting in possible failure or

collapse. Adequate drainage should be a part of any dust col-

lector with water sprinkler options.

3.6.10.1 Sprinkler Coupler

Optional sprinkler couplers are provided on the SFC unit for the

convenience of fire control system professionals. The buyer or

owner/user is responsible to supply, install and test the sprinkler

head and any related or required fire control system devices,

components or accessories. It is the responsibility of the buyer

or owner/user to test functionality and operation of the fire

control system for water leakage, correct installation, appropri-

ate fire control system component location, correct operation

and appropriate application while strictly adhering to any and

all prescribed AHJ, OSHA, NFPA, Federal, State/Provincial and

Local codes, standards, regulations and instructions appli-

cable to industrial dust collectors, fire control systems and any

related and required components and processes.

3.6.10.2 Sprinkler Head

If a sprinkler head is requested to be installed at the factory, it is

the sole responsibility of the buyer or owner/user to supply the

applicable and desired sprinkler head device or sprinkler head

specification including manufacturer and part number and any

special installation instructions. It is also the responsibility of the

buyer or owner/user to test functionality and operation of the

sprinkler head and the fire control system for water leakage,

correct installation, appropriate fire control system component

location, correct operation and appropriate application while

strictly adhering to any and all prescribed AHJ, OSHA, NFPA,

Federal, State/Provincial and Local codes, standards, regula-

tions and instructions applicable to industrial dust collectors,

fire control systems and any related and required components

and processes.

4. Operation

Shut off unit disconnect and lock out all electrical power

to the dust collector prior to performing service work.

!

D A N G E R

!

D A N G E R

Summary of Contents for SFC

Page 1: ...Downward Flow Cartridge Dust Collector Owner s Manual Model SFC...

Page 7: ...v Page intentionally left blank...

Page 11: ...4 FIGURE 2 SFC Typical SINGLE UNIT Installation Diagram PARKER PARKER 44 10335 0001...

Page 12: ...5 FIGURE 3 Recommended Unit Clearances 44 10337 0001...

Page 14: ...7 FIGURE 4 Single Hopper SFC 44 10309 0001...

Page 15: ...8 FIGURE 5 Multiple Hopper SFC 44 10309 0002...

Page 16: ...9 FIGURE 6 Multiple Hopper SFC 44 10309 0003...

Page 17: ...10 FIGURE 7 Multiple Modules SFC 44 10310 0001...

Page 19: ...12 FIGURE 8 SFC Pressure Gauge Installation 44 10333 0001 Rev A...

Page 20: ...13 FIGURE 9 Solenoid Wiring to Pulse Controls for 2 3 4 and 5 Tier Units...

Page 21: ...14 FIGURE 10 Pneumatic Valve Assembly 44 10332 0001...

Page 24: ...17 FIGURE 12 Abrasive Inlet Installation 44 10338 0001...

Page 27: ...20 FIGURE 16 EDAP Interconnection FIGURE 15 EDAP Installation 48 10007...

Page 30: ...23 FIGURE 17 SFC Series Door Filter Installation 44 10329 0001...

Page 37: ...30 7 Illustrated Parts FIGURE 21 SFC Series 44 10330 0001 FIGURE 22 SFC Series Explosion Vents...