1-12-2-1-5

1

• When brazing, must be cool the pipe by wet cloths after removing the insulation

tube and the cover plate.

• When brazing the gas tubing, cool the tubing with dampened shopcloths as you

work, as shown in the figure below, to protect the unit’s thermistor rom the heat

generated by brazing.

• When brazing, be careful not to heat the electrical component box.

Doing so may cause the unit to be damaged.

Insulation tube

Cover plate

Wet cloth

• Pipe insulation must be made after leak detection for tubing connection area was performed.

• Be sure to insulate both the gas tubing and liquid tubing.

In addition, wrap the supplied insulation material around the tubing joints, and fasten in place with vinyl tape or other means.

Failure to insulate the tubing may result in water leakage from condensation.

• Plug all gaps at tube through-holes in the unit with insulation or a similar substance to prevent air leakage.

Installing the Drain Piping

1.

Before Performing the Installation Drain Piping

(1) Prepare standard hard PVC pipe (O.D. 32 mm) for the drain and use the supplied drain bsocket to prevent water leaks.

The PVC pipe must be purchased separately.

When doing this, apply adhesive for the PVC pipe at the connection point.

See section “2. Installing the Drain Pipe”on page 1-12-2-1-6.

(2) Limitations of Drain Hose Connection

CAUTION

Do not make a trap in the middle of the supplied drain pipe.

Doing so will cause abnormal sound.

Trap prohibited

(3) Ensure the drain pipe has a downward slant (1/100 or more).

Downward slant

Min. 1/100

Correct

Incorrect

(4) The drain pipe with a trap should be installed away from the indoor unit.

(5) Do not attach any air purge equipment.

If attached, drain water may result in splashing out of the drain pipe.

(6) When the drain piping is completed, perform the water leak test and check for a water leak.

If detected, it may result in water leakage or condensation.

(7) When the drain piping is completed, perform the drainage test if the water drains smoothly.

If not draining smoothly, it may result in water leakage or condensation.

(8) When the drain piping work is finished securely, wrap the insulation material around the indoor side drain pipe.

At this time, do not wrap together with the refrigerant tubing.

If wraped together, the drain pipe is lifted and water drainage will not be operated.

Consequently, the water comes out of the drain pan and it can lead to water leakage.

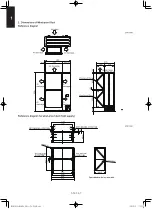

*

a

*

b

Inspection plug

*a: over 100mm

*b: over 50mm

Note:

Since the drain trap area easily

accumulates the dust inside the drain

pipe, necessarily install the plug in

order to clean out the drain trap.

• The type 200 indoor unit comes with a connection tubing that is for

liquid tubing. Configure as shown in the illustration and connect it.

When flaring the tube, put the flare nut onto it first and then flare it.

Remove the ø12.7 flare nut from the liquid

tubing of the indoor unit and use it.

To indoor unit

Flare the tubing

Connection tubing

for type 200 (Accessory)

Braze

ø 9.52

To outdoor unit

SM830276-00_欧州向け R32シングル TD&SM.indb 5

2019/02/27 11:54:44

Summary of Contents for Elite Big PAC-i S-200PE3E5B

Page 12: ...MEMO Xi SM830276 00_ R32 TD SM indb 12 19 02 26 15 26 22...

Page 160: ...1 14 8 MEMO SM830276 00_ R32 TD SM indb 8 2019 02 27 11 55 39...

Page 176: ...MEMO 2 16 SM830276 00_ R32 TD SM indb 16 19 02 28 13 23 00...

Page 182: ...MEMO 3 6 SM830276 00_ R32 TD SM indb 6 19 02 26 10 39 17...

Page 238: ...MEMO 5 38 SM830276 00_ R32 TD SM indb 38 19 02 28 13 29 52...

Page 316: ...201903 SM830276 00_ R32 TD SM indb 1 19 02 15 8 52 12...