339

JAN 2006

Ver. 5.2

DP-3510/3520/3530/4510/4520/4530/6010/6020/6030

8.17. Installing the DD Server Software (DA-WS20)

8.17.1. Contents

Note:

1. The part number may differ depending on the Destination.

2. Refer to the Parts List in the Parts Manual.

8.17.2. Installation

Install the DD Software into the PC with the Operating Instructions by following the prompts of the

Installation Wizard.

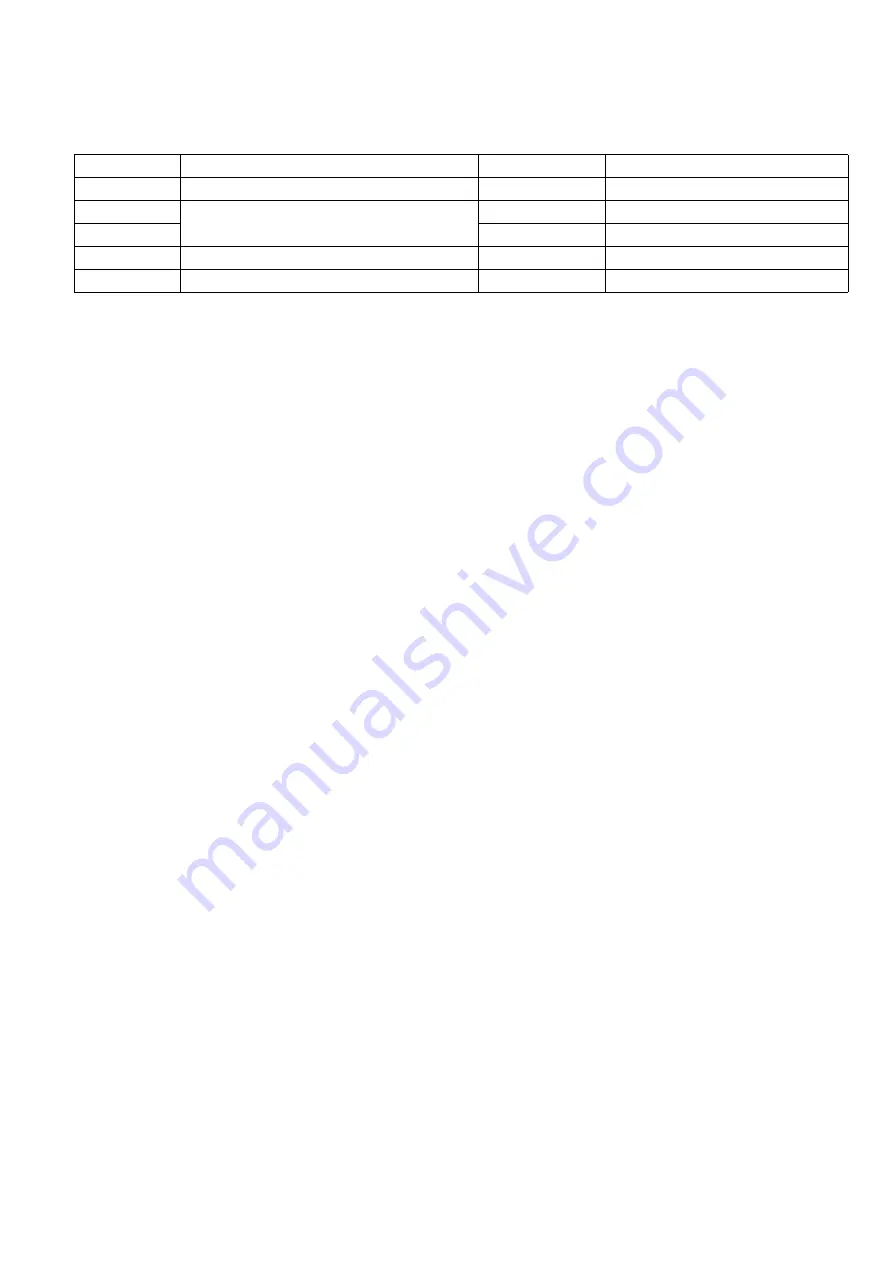

Qty.

Description

Part No.

Remarks

1

DD Server Software CD

See Note

Includes Operating Instructions

1

License Agreement

DZSH000112

For USA and Canada only

1

DZSH000113

For Other Destinations

1

DD Server Operating Instructions

DZSD001791

1

Installation Instructions

DZSM000574

This document

Summary of Contents for DP-3530

Page 4: ...4 Beispiel DP 6530 4530 6030 Hinweis ...

Page 424: ...424 JAN 2006 Ver 5 2 DP 3510 3520 3530 4510 4520 4530 6010 6020 6030 ...

Page 425: ...425 JAN 2006 Ver 5 2 DP 3510 3520 3530 4510 4520 4530 6010 6020 6030 ...

Page 474: ...474 JAN 2006 Ver 5 2 DP 3510 3520 3530 4510 4520 4530 6010 6020 6030 memo ...

Page 842: ...memo ...

Page 858: ...DZZSM00298 ...