7

Palmgren Operating Manual & Parts List

84315

OPERATION (CONTINUED)

•

Pull out the removable key. The key has the words,“Remove to

Lock”.

•

Store key in a safe place

NOTE:

With the key removed, the rocker can be “ROCKED”, but the

switch cannot be actuated.

To unlock the lathe:

•

Position the rocker in the OFF position.

•

Insert the key into the rocker.

•

Connect line cord to power source.

•

The switch can now be actuated.

CHANGING SPEEDS

To vary spindle speeds, rotate speed control knob to the desired

setting. Refer to speed chart for specific turning operations.

CAUTION:

Change speeds only while motor is running:

SPINDLE TURNING

If you have never done any amount of wood turning, we suggest

that you practice using the various wood turning tools. Start with

a small spindle turning.

Be sure to study the following pages of this manual. They explain

and illustrate the correct use of the turning tools, the positioning

of the tool rest, and other information to help you gain experience.

•

Select a piece of wood 2

″

x 2

″

x 12

″

.

•

Draw diagonal lines on each end to locate the centers.

•

On one end, make a saw cut approximately

1

/

16

″

deep on each

diagonal line. This is for the spur center.

•

The other end uses the bearing center. Place the point of the

bearing center on the wood where the diagonal lines cross.

•

Drive the bearing center into the wood. Use a wooden mallet or

a plastic hammer, but put a piece of wood on the end of the

bearing center to protect it from harm.

•

Remove the bearing center and drive the spur center into the

other end of the wood. Make sure the spurs are in the saw cuts.

Remove the spur center.

•

Make sure the centers and the hole in the spindle and the tail

stock ram are clean. Insert the spur center into the headstock

and the bearing center into the tail stock. Tap them in lightly

with a piece of wood. Do not drive them in.

•

If the tail stock center is not of the ball bearing type, put a drop

of oil or wax on the wood where it contacts the center. This will

lubricate the wood while it is turning.

•

Place the wood between the centers and lock the tail stock.

•

Move the bearing center into the wood by turning the hand

wheel. Make sure that the bearing center and spur center are

“seated” into the wood in the holes made earlier. Rotate the

wood by hand while turning the hand wheel.

•

Adjust the tool rest approximately

1

/

8

″

away from the corners of

the wood and

1

/

8

″

above the center line. Note the angled posi-

tion of the tool rest base. Lock the tool rest base and the tool

rest.

•

Observe the speed chart (see page 16). For example, a 2

″

square turning up to 18

″

long should run at 1100 RPM for

“roughing”. Rotate the wood by hand to make sure that the cor-

ners do not strike the tool rest and verify that the indexing pin

is not engaged.

INDEXING

Refer to Figure 18.

The spindle pulley has 24 equally spaced holes (15° apart).The index

pin passes through the spindle pulley, engages with one of the 24

holes and locks the spindle from turning while you put a mark on

the workpiece.

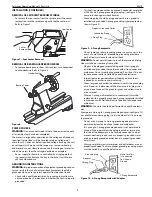

Rocker Switch

Speed Control Knob

Removable Key

Figure 13

Figure 15

Figure 16

Figure 14

Diagonal Lines

on Both Ends

Figure 17

Figure 18

Index Pin Lever

Spindle Pulley