23

Palmgren Operating Manual & Parts List

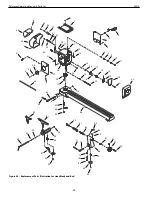

84315

Ref.

No. Description

Part No.

Qty.

1

3AMI-25 Retaining Ring

01900.00

2

2

Cap

18013.00

1

3

Spring Retainer

18014.00

1

4

Spring

18015.00

1

5

Movable Spindle Pulley

18016.00

1

6

Variable Speed Belt

18017.00

1

7

5 x 5 x 30mm Key

08438.00

1

8

6-1.0 x 8mm Set Screw

01043.00

3

9

Stationary Spindle Pulley

18018.00

1

10

3AMI-20 Retaining Ring

00256.00

1

11

6204zz Ball Bearing

00989.00

4

12

8-1.25 x 12mm Socket Head Bolt

*

3

13

Spindle Cover

18019.00

1

14

Spindle O-ring

18020.00

1

15

6305zz Ball Bearing

06966.00

1

16

5 x 5 x 25mm Key

00975.00

1

17

Spindle

18021.00

1

18

Spacer

18022.00

1

19

3BMI-62 Retaining Ring

07843.00

1

20

6-1.0 x 16mm Socket Head Bolt

01760.00

6

21

6mm Lock Washer

*

8

22

Plate

18023.00

1

23

Bearing Retainer

18024.00

1

24

Stationary Drive Pulley

18025.00

1

25

Movable Drive Pulley

18026.00

1

26

51107 Bearing

18027.00

1

27

5 x 5 x 14mm Key

18028.00

2

28

Transmission Shaft

18029.00

1

29

Pin

18030.00

1

30

6-1.0 x 20mm Socket Head Bolt

*

4

31

Transmission Shaft Support

18031.00

1

32

Bearing Cap

18032.00

1

33

6205zz Ball Bearing

02443.00

1

34

3BMI-52 Retaining Ring

02445.00

1

35

5-0.8 x 25mm Socket Head Bolt

05284.00

2

36

5mm Lock Washer

*

2

37

Retainer

18033.00

2

38

Nut

18034.00

1

39

5-0.8mm Hex Nut

*

2

40

Link

18035.00

1

41

Adjusting Rod

18036.00

1

42

Retainer

18037.00

1

Ref.

No. Description

Part No.

Qty.

43

6-1.0 x 12mm Flat Head Screw

08567.00

4

44

5-0.8 x 6mm Set Screw

03069.00

1

45

Gear

18038.00

1

46

5-0.8 x 10mm Flat Head Screw

07458.00

1

47

Flange

18039.00

1

48

Gear

18040.00

1

49

Transmission Pulley

18041.00

1

50

Drive Belt

18042.00

1

51

Spacer

18043.00

1

52

6-1.0 x 12mm Socket Head Bolt

*

1

53

6mm Flat Washer

*

1

54

Motor Pulley

18044.00

1

55

Motor Housing, Rear

18045.00

1

56

Stator

18046.00

1

57

Armature

18047.00

1

58

Motor Housing, Front

18048.00

1

59

8mm Lock Washer

*

2

60

8-1.25 x 135mm Socket Head Bolt

18049.00

2

61

Starting Capacitor

00296.00

1

62

Capacitor

18050.00

1

63

Plate

18051.00

1

64

5-0.8 x 10mm Pan Head Screw

*

2

65

4-0.7 x 10mm Pan Head Screw

01903.00

2

66

4mm Flat Washer

*

2

67

Terminal Block

18052.00

1

68

Fan Transmission Shaft

18053.00

1

69

3AMI-12 Retaining Ring

00519.00

2

70

6001zz Ball Bearing

21116.00

2

71

Collar

18054.00

1

72

Bracket

18055.00

1

73

Air Manifold

18056.00

1

74

Fan Housing

18057.00

1

75

Fan

18058.00

1

76

5mm Flat Washer

*

1

77

5-0.8 x 12mm Socket Head Bolt

*

1

78

Fan Housing Cover

18059.00

1

79

5-0.8 x 10mm Tap Screw

18060.00

2

80

Vent Tube

18061.00

1

81

Headstock Body

18082.09

1

82

4

″

Faceplate

06991.00

1

83

#2MT Spur Center

06969.00

1

∆

Operator's Manual

21124.09

1

R

RE

EP

PL

LA

AC

CE

EM

ME

EN

NT

T P

PA

AR

RT

TS

S L

LIIS

ST

T F

FO

OR

R S

SP

PIIN

ND

DL

LE

E A

AN

ND

D D

DR

RIIV

VE

E A

AS

SS

SE

EM

MB

BL

LY

Y

* Standard hardware item available locally.

∆

Not Shown