14

Palmgren Operating Manual & Parts List

84315

OPERATION (CONTINUED)

MAKING LONG CONVEX CUTS

•

First, turn work down to approximate size, using sizing cuts (as

required) to determine various diameters. Finish cuts can then

be made with either skew or gouge.

•

If the skew is used, the principles of the operation are the same

as those employed in cutting a bead – except that the curve is

longer and may be irregular. Use the extreme heel throughout

– start at longer end of curve (if curve is irregular) and progress

toward steeper end.

•

If gouge is used, make cut in the same direction. Start with the

handle well back of point – swinging handle in the direction of

tool travel to overtake the point, if necessary, when the steep

part of the curve is reached. Object is to have the extreme

point doing the cutting throughout with the bevel as tangent

to curve as possible.

MAKING LONG TAPER CUTS

Long taper cuts are made like long convex cuts, with the skew or

gouge. However, the angle between the cutting edge and handle is

kept constant during the entire cut.The handle is not swung around.

•

Always cut downhill. Do not cut too deeply at the center of the taper.

SPINDLE TURNINGS

PLOTTING THE SHAPE

Once the basic cuts have been mastered, you are ready to turn out

finished work.

•

The first step is to prepare a plan for the proposed turning. This

can be laid out on a suitable sheet of paper. The layout should

be to full size.

•

Next, prepare the turning stock by squaring it up to the size of

the largest square or round section in your plan. The stock can

be cut to the exact length of the proposed turning. However, in

most cases, it is best to leave the stock a little long at one or

both ends to allow for trimming.

•

Mount the stock in the lathe and rough it off to a maximum-

size cylinder.

•

Now, project your plan onto the turning by pencil marking the

various critical dimensions along the length of the spindle.

These dimensions can be laid out with an ordinary ruler or by

using a template. Make the pencil marks about

1

/

2

″

long so they

will be visible when the work is revolved under power. The lines

can be quickly traced around the spindle by touching each line

with the pencil.

•

After marking, use the parting tool to make sizing cuts at all of

the important shoulders. When learning, you will find it best to

make sizing cuts to accurately plot the various diameters.

Experienced wood workers can manage with fewer such cuts at

the important shoulders.

•

Plan each sizing cut so that it is in waste stock and make each

cut deep enough so that there will be just enough wood left

under the cut for the finishing process.

•

Once the sizing cuts have been completed, rough-out the

excess wood with a gouge. Then, proceed with the finishing

process by making the various types of cuts required.

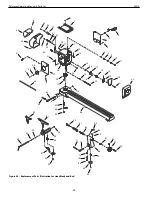

RECOMMENDED SPEED

Always follow recommended speed to do spindle turning depend-

ing upon the size and length of workpiece.

DUPLICATE TURNINGS

Identical turnings require great accuracy when plotting the work

and performing the various cuts. Many methods have been

devised to aid in perfecting the work.

Use of Patterns

Professional workers generally use a pattern or layout board. This is

a thin piece of wood or cardboard upon which is drawn a full-size

half section of the turning. The contour of the finished surface is

drawn first. Then, the diameters at various critical points are drawn

to scale as vertical lines intersecting the contour line.

•

By placing the pattern against the roughed-out cylinder, you

can quickly mark the various points of the critical diameters.

•

To make each sizing cut, use outside calipers and set these by

actually measuring the length of the vertical lines on the pat-

tern which represent the diameters desired. Make the sizing cut

down to the proper diameter by using the calipers to deter-

mine when the cut is finished.

•

After making the sizing cuts, hang the pattern behind the lathe

where it will serve as a guide for completion of the workpiece.

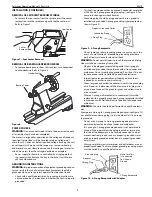

Figure 48 – Chisel Inclined in Direction of Cut

Figure 50

SQUARE

1 to 2

″

1 to 2

″

1 to 2

″

2 to 4

″

2 to 4

″

2 to 4

″

4

″

Plus

4

″

Plus

4

″

Plus

LENGTH

1 to 12

″

to 24

″

to 38

″

1 to 12

″

to 24

″

to 38

″

1 to 12

″

to 24

″

to 38

″

ROUGH

RPM

1300

1100

1000

1000

900

700

800

600

400

FINISH

RPM

2000

2000

2000

1800

1600

1400

1400

1100

800

Tenon

Diameters

1

1

/

4

″

1

1

/

2

″

1

1

/

2

″

1

1

/

4

″

1

3

/

4

″

1

7

/

8

″

1

11

/

16

″

1

1

/

4

″

1

9

/

16

″

14

1

/

4

″

2

1

/

16

″

2

1

/

4

″

2

1

/

4

″

2

1

/

4

″

2

″

1

″

Sizing Cuts

Figure 49

3

1

/

8

″