D

DE

ES

SC

CR

RIIP

PT

TIIO

ON

N

Palmgren 38

″

variable speed wood lathe provides capability to

turn wooden workpieces up to 38

″

long and 4

″

diameter. This lathe

can also turn bowls up to 15

″

diameter and 4

″

thick. The motor

rotates at 1725 RPM and the spindle speeds are 360-2400 RPM.

Extended spindle allows convenient outboard turning.

U

UN

NP

PA

AC

CK

KIIN

NG

G

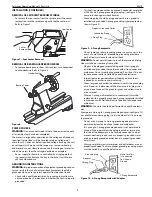

Refer to Figure 1.

Check for shipping damage. If damage has occurred, a claim must

be filed with carrier. Check for completeness. Immediately report

missing parts to dealer.

Your wood lathe is shipped complete in one carton and includes a

motor. Separate all parts from packing materials and check each

one with the unpacking list to make certain all items are account-

ed for before discarding any packing material.

If any parts are missing, do not attempt to assemble the lathe, plug

in the power cord, or turn the switch on until the missing parts are

obtained and properly installed.

A Headstock Assembly

B Bed

C Tailstock Assembly

D Tool Rest Base Assembly

E Handle

F Parts Bag

G 12

″

Tool Rest

H 6

″

Tool Rest

IMPORTANT:

The bed is coated with a protectant. To ensure prop-

er fit and operation, remove coating. Coating is easily removed

with mild solvents, such as mineral spirits, and a soft cloth. Avoid

getting cleaning solution on paint or any of the rubber or plastic

parts. Solvents may deteriorate these finishes. Use soap and water

on paint, plastic or rubber components. Wipe all parts thoroughly

with a clean dry cloth. Apply paste wax to the bed.

SPECIFICATIONS

Turning length (max.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

″

Bowl diameter (max.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

″

Overall length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

″

Overall height . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

″

Width . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

″

Spindle Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 360 to 2400 RPM

Spindle Taper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2MT

Spindle Thread . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

″

-8

Tail Stock Taper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2MT

Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . SP, Locking rocker

Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120/240V, 12/6 AMPS

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175 lbs

S

SA

AF

FE

ET

TY

Y R

RU

UL

LE

ES

S

CAUTION:

Always follow proper operating procedures as defined

in this manual – even if you are familiar with use of this or similar

tools. Remember that being careless for even a fraction of a second

can result in severe personal injury.

BE PREPARED FOR JOB

•

Wear proper apparel. Do not wear loose clothing, gloves, neck-

ties, rings, bracelets or other jewelry which may get caught in

moving parts of machine.

•

Wear protective hair covering to contain long hair.

•

Wear safety shoes with non-slip soles.

•

Wear safety glasses complying with United States ANSI Z87.1.

Everyday glasses have only impact resistant lenses. They are

NOT

safety glasses.

•

Wear face mask or dust mask if operation is dusty.

•

Be alert and think clearly. Never operate power tools when

tired, intoxicated or when taking medications that cause

drowsiness.

PREPARE WORK AREA FOR JOB

•

Keep work area clean. Cluttered work areas invite accidents.

•

Do not use power tools in dangerous environments. Do not use

power tools in damp or wet locations. Do not expose power

tools to rain.

•

Work area should be properly lighted.

•

Keep visitors at a safe distance from work area.

•

Keep children out of workplace. Make workshop childproof. Use

padlocks, master switches or remove switch keys to prevent

any unintentional use of power tools.

•

Keep power cords from coming in contact with sharp objects,

oil, grease, and hot surfaces.

TOOL SHOULD BE MAINTAINED

•

Always unplug tool prior to inspection.

•

Consult manual for specific maintaining and adjusting

procedures.

•

Keep tool lubricated and clean for safest operation.

•

Keep all parts in working order. Check to determine that the

guard or other parts will operate properly and perform their

intended function.

•

Check for damaged parts. Check for alignment of moving parts,

binding, breakage, mounting and any other condition that may

affect a tool's operation.

•

A guard or other part that is damaged should be properly

repaired or replaced. Do not perform makeshift repairs. (Use

parts list provided to order replacement parts.)

•

Never adjust attachments while running. Disconnect power to

avoid accidental start-up.

•

Have damaged or worn power cords replaced immediately.

•

Keep cutting tools sharp for efficient and safest operation.

2

Palmgren Operating Manual & Parts List

84315

Figure 1 – Unpacking

A

D

C

E

H

B

G

F