20

Palmgren Operating Manual & Parts List

84315

OPERATION (CONTINUED)

USE OF SANDING DRUMS

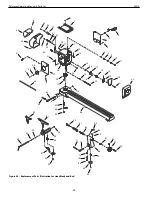

Refer to Figure 77.

Standard sanding drums are usually rubber cylinders which can be

expanded to hold an abrasive sleeve in place. Similar cylinders,

turned on the lathe and covered with abrasive paper, will be ade-

quate for the job. These have the advantage that special sizes,

tapers, etc. can be made. Adhesive papers must be glued to the

cylindrical surface precisely and completely.

The drum is used mainly for sanding the edges of curved work.

•

The squareness of the edge of the work can be best retained by

using a simple form of vertical fence as shown.

•

The standard sanding drums are commonly made with a

threaded hole to fit the lathe drive spindle.

•

To guard against loosening of the taper shank while the drum

is in operation, it is advisable to support the free end, using

either a ballbearing or plain 60° center in the tail stock.

USE OF WOOD CHUCKS FOR SANDING

Quick-acting chucks can be very useful for sanding operations on

duplicate production parts. The chuck is made slightly oversized,

and a piece of rubber hose (for small parts) is inserted in the recess

to grip the workpieces.

M

MA

AIIN

NT

TE

EN

NA

AN

NC

CE

E

WARNING:

Make certain that the unit is disconnected from power

source before attempting to service or remove any component.

CLEANING

Keep machine and workshop clean. Do not allow sawdust to accu-

mulate on the tool. Keep centers clean.

Be certain motor is kept clean and is frequently vacuumed free of

dust.

Use soap and water to clean painted parts, rubber parts and plastic

guards.

LUBRICATION

The shielded ball bearings in this tool are permanently lubricated

at the factory. They require no further lubrication.

KEEP TOOL IN REPAIR

•

If power cord is worn, cut, or damaged in any way, have it

replaced immediately.

•

Replace any damaged or missing parts. Use parts list to order

parts.

Any attempt to repair motor may create a hazard unless repair is

done by a qualified service technician. Repair service is available at

your nearest Palmgren store.

REPLACING WORN FAN BELT

Refer to Figure 79.

•

Remove upper rear cover (1 screw).

•

Remove top cover (4 screws).

•

Remove front cover.

•

Remove and replace belt.

•

Assemble in reverse order.

REPLACING WORN VARIABLE SPEED BELT

Refer to Figures 79 and 80.

NOTE:

a mechanical jaw puller and snap ring pliers are required to

perform this operation.

•

Remove upper rear cover (1 screw).

•

Remove top cover (4 screws).

•

Remove rear cover (4 screws).

•

Remove snap ring from drive shaft.

•

Remove 4 socket head bolts from plate.

•

Using puller, remove plate, bearing and pulley.

•

Remove snap ring, cap, spring and pulley from spindle shaft.

CAUTION:

Cap is spring loaded and in tension.

•

Remove and replace belt.

•

Assemble in reverse order.

Figure 80

Top Cover

Rear Cover

Front Cover

Figure 79

Upper Rear

Cover

Drive Shaft

Spindle

Plate

Cap

Figure 77

Figure 78