33

ASSEMBLING THE WINCH GEAR TRAIN, BRAKE AND DRUM

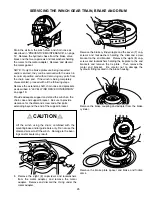

Before beginning to assemble the winch, all bearings

should be cleaned, inspected and replaced as required.

All seals should be replaced. Use a good grade non-

hardening sealing compound on the outside diameter of

seals and a light coat of thread sealing compound or

sealing tape on pipe fittings and plugs. Be careful not to

get these materials inside parts and passages which

conduct oil.

Planet carrier assemblies and brake cylinder should be

serviced as required. New O-rings, backup rings and

motor gasket should be on hand. All bushings and

thrust washers should be inspected and replaced as

required.

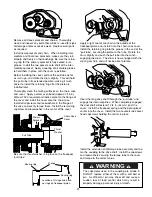

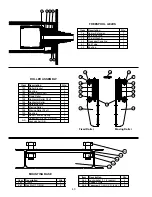

Place the chain case end support bracket on a clean

work surface. Use wooden blocks to level and raise the

bracket approximately 4 to 6 inches since the end of the

drum and the pull tube will extend approximately 1 1/2

inches past the bracket when installed. The drum bear-

ing, retaining ring and seal should already be installed.

The diamond screw bearing and seal should also be

installed.

Set the drum onto the support bracket, being careful not

to damage the seal.

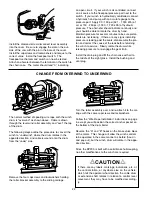

Install the pull tube and freespool gear assembly into the

drum. Install the drum bushing (item 17) onto the pilot

hub inside the drum. Install the planet carrier extension

(item 16) into the drum. The end of the extension will fit

over the drum bushing.

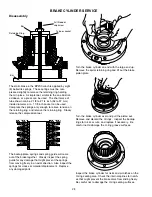

Lower the output planet carrier assembly into the drum,

making certain that the teeth on the end of the carrier

mesh with the teeth on the carrier extension.

Install the ring gearwith the beveled end down, toward

the carrier extension.. The ring gear teeth must mesh

with the output planet gears.

Summary of Contents for Braden BP200

Page 46: ......