8

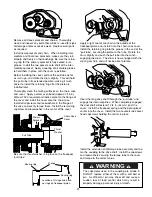

opening toward the diamond screw. Disengage the dia-

mond screw by rotating the lever on the chain case, 90o

toward the front of the winch. Using the handwheel on

the motor end of the winch, turn the diamond screw in the

same direction as the winch hauls in cable until the roller

bracket is at the flange where the cable will be anchored.

The pawl should be just starting to enter the turnaround

area of the screw. Re-engage the diamond screw.

Thread the wire rope through the spring loaded rollers

and anchor it to the winch drum. Refer to the figures on

the previous page for additional information. When

spooling cable onto the drum, the roller bracket should

lag behind where the rope is laying onto the drum by 1/2

of a rope diameter. Re-adjust the position of the roller

assembly, if needed, after beginning to spool wire rope

onto the drum. The diamond screw levelwind alone does

not assure smooth even spooling of cable onto the drum.

A light load (approx. 200 to 400 LB , 90 to 180 kg) should

be maintained on the cable to assist even spooling.

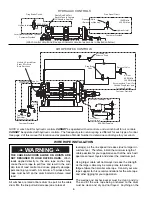

DIMENSIONAL DRAWINGS AND SPECIFICATIONS

HAUL-IN

DIAMOND SCREW

IS IN THIS POSITION

ENGAGED

1.125

FREESPOOL

PORT

SAE -4 ORB

(7/16 - 20 THD)

35.52

(902)

22.53

(572)

17.66

(449)

14.96

(380)

12.98

(330)

29.00

(737)

11.87

(302)

16.87

(429)

11.38

(289)

22.76

(578)

DISENGAGED WHEN HANDLE

Internal brake effective both directions

Minimum 150 psi (1,030 kPa), above motor outlet pressure, required to shift motor to high speed

Maximum allowable pressure at motor shift port - 2,500 psi (17,200 kPa)

Shaft end motor case drain must be drained to tank

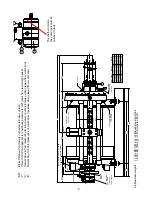

Layer

LBS

kN

FPM

MPM

LBS

kN

FPM

MPM

FT

M

1

20,000

89.0

44

13

9,860

43.9

88

27

148

45.1

2

18,440

82.0

48

15

9,090

40.4

96

29

309

94.2

3

17,110

76.1

52

16

8,440

37.5

104

31

482

147

4

15,960

71.0

55

17

7,870

35.0

111

34

668

204

5

14,950

66.5

59

18

7,370

32.8

119

36

866

264

6

14,060

62.5

63

19

6,930

30.8

126

38

1,077

328

7

13,270

59.0

67

20

6,540

29.1

134

41

1,301

397

8

12,570

55.9

70

21

6,200

27.6

141

43

1,537

469

Rope Capacity

9/16 in. (14 mm)

Low Speed

Line Pull

Line Speed

High Speed

Line Pull

Line Speed

2 speed motor displacement is

21.2/10.6 cu in. (347/173 cu cm).

Performance based on:

2,500 psi (17,200 kPa) at

30 gpm (114 LPM)

Other Rope Capacities:

1/2 in. - 2,226 ft (678 M)

7/16 in. - 2,769 ft (844 M)

NOTE: Continuous operation at

high speeds and loads may

require the use of an oil cooler in

the hydraulic system to maintain

acceptable oil temperature.

Dimensions shown are

inches (millimeters)

Summary of Contents for Braden BP200

Page 46: ......