36

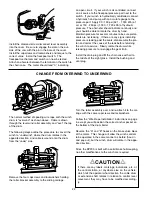

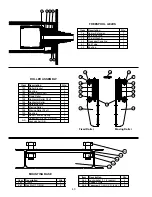

Measure the brake stack-up as shown. The measure-

ment should be a minimum of 0.1875 in. (4.75 mm) from

the top of the brake plate spacer to the top of the brake

cylinder. If the measurement is less than this, remove

the brake plate spacer and add a steel brake disc to the

top of the brake pack. Replace the brake plate spacer

and repeat the procedure. Do not exceed an overall

height of 0.25 in. (6.35 mm).

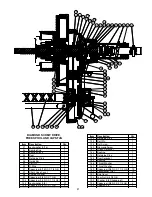

Install the motor end support bracket and the tie plate

between the two end brackets. Install all capscrews and

lockwashers, but do not fully tighten them at this time.

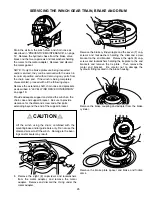

Install the brake cylinder nipple, using a good grade of

thread sealant.

Lubricate the o-ring and install it on the outside of the

brake cylinder. Push it down until it’s resting against the

motor end plate.

Install the motor adapter with eight (8) capscrews and

lockwashers. Use a new gasket and install the motor

onto the motor adapter.

If the slide bars were removed, install them using two

new roll pins. Install the diamond screw into its bearing

in the chain case suport bracket, being careful not to

damage the seal. Install the slider bracket onto the slide

bars and engage the pawl into the diamond screw.

Install the level wind support bracket over the diamond

screw and slide bars, being careful not to damage the

seal. Tighten all capscrews in the bracket and the tie

plate to their correct torque values.

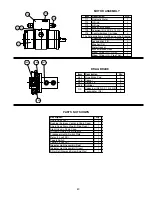

Refer to “SERVICING THE DIAMOND SCREW LEVEL

WIND” for additional information and install the bearing

and cover plate.

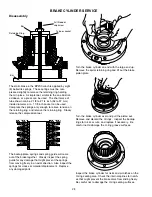

Turn the winch onto its mounting feet, and raise the

chain case end up approximately 2 to 3 in. (51 to 76

mm).

Check the diamond screw end play with a dial indicator

as shown. End play should be 0.010 to 0.015 in. (0.25

to 0.38 mm). Adjust end play by adding or removing

shims under the cover plate at the opposite end of the

diamond screw. When proper end play is achieved,

install the diamond screw handwheel.

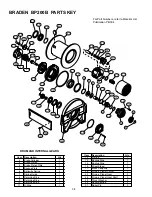

Summary of Contents for Braden BP200

Page 46: ......