21

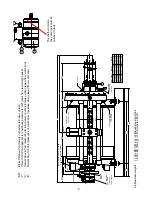

Remove all three sprockets and chains. Thoroughly

clean and inspect any parts that will be re-used for signs

of damage and/or excessive wear. Replace worn parts

as required.

Install new sprockets and chain. When installing inter-

mediate and final drive sprockets, make sure they turn

smooth and freely on their bushings. Be sure the retain-

ing ring for the primary sprocket is fully seated in its

groove. Install the two spacers onto shaft of the inter-

mediate sprocket. Apply a coating of oil soluble grease

to hold them in place until the cover is installed.

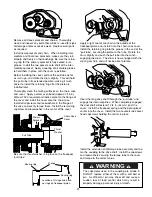

Before installing the cover, pull out the pull tube as far

as it can go, and rotate the drum slightly. This will hold

the pull tube in its extended position, making it much

easier to install the retaining ring after the piston is

installed later.

Thoroughly clean the mating surfaces on the chain case

and cover. Apply a small, even bead (approx. 3/16 in.)

of Dow 732 or equivalent silastic sealant to the flange of

the cover and install the cover onto the chain case.

Install all capscrews and lockwashers in the flange of

the case and evenly torque them. Install the remaining

capscrew and lockwasher in the center of the cover.

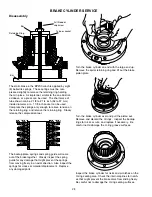

Be sure the thrust washer is in place on the freespool

“pull tube”

Pull Tube

Thrust

Washer

Primary

Sprocket

Chain Case

Cover

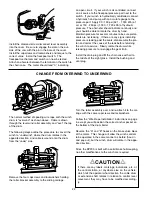

Apply a light coat of winch oil to the outside of the

freespool piston and install it into the chain case cover.

Install the retaining ring into the groove in the end of the

“pull tube”, securing the piston to the tube. Rotate the

drum slightly and push the pull tube into the winch,

engaging the drum. The drum is now engaged with the

winch gear train and will not be able to rotate.

Insert the long drive shaft through the “pull tube” and

engage the internal splines. When completely engaged,

the driveshaft will extend 1 3/4 in. (44 mm) past the

cover. Install the freespool spring and the bearing/seal

carrier into the cover. Install the two countersunk socket

head capscrews holding the carrier in place.

Install the extension shaft/torque tube assembly and fas-

ten the coupling to the drive shaft. Install the capscrews

and lockwashers securing the torque tube to the cover

and torque to the correct value.

The capscrews used in the coupling are Grade 8.

DO NOT replace either of them with a soft bolt or

pin. A soft bolt or pin may shear off and cause a

sudden loss of load control which may result in

property damage, personal injury or death.

CAUTION

WARNING

!

!

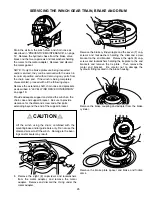

Location of O-rings and back-

up rings on freespool piston.

O-rings

Backup ring

Backup ring

Summary of Contents for Braden BP200

Page 46: ......