77

Chapter 6

W

elding Condition

S

ETTING

W

ELDING

C

ONDITIONS

W

ELDING

C

ONDITION

C

HAPTER

6

2.

Turn the parameter adjustment knob, and change the setting value.

3.

Press the WAVE FRQ key or the DISPLAY CHANGE key.

B

Adjustment of wave frequency is complete.

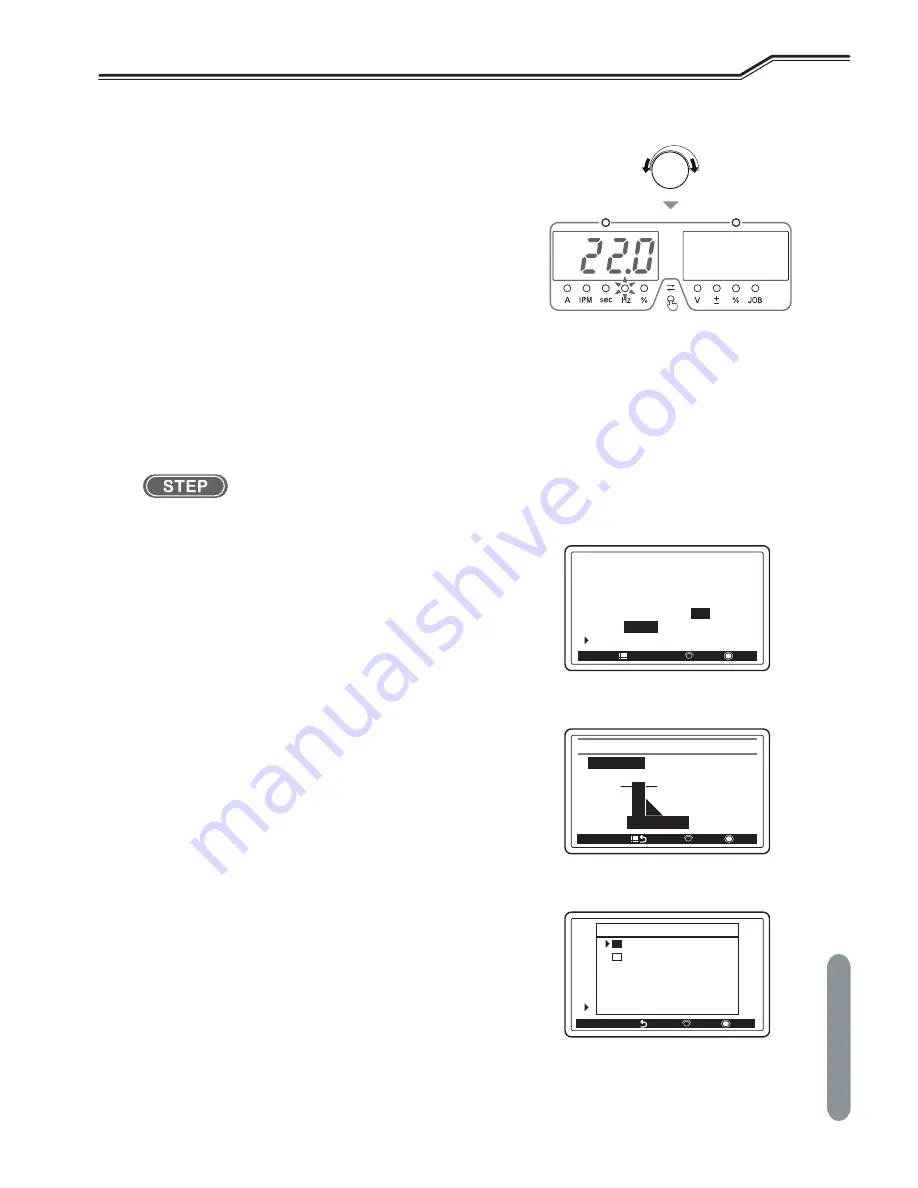

6.6.10 Welding guide

By setting the "WELD JOINT" and "PLATE THICKNESS", the welding current will be set automatically according to each

parameter.

1.

Select "WELDING GUIDE" on the HOME screen.

2.

Turn the screen operation knob and select "WELD JOINT", then press the screen operation knob.

3.

Select the weld joint that needs to be changed.

●

Adjust the value between 0.5 to 32 Hz.

●

Turn the screen operation knob and point the cursor to

WELDING GUIDE, then press the screen operation knob.

B

WELDING GUIDE screen is displayed.

B

The color of the selected parameter will be inverted on the

display.

●

Turn the screen operation knob to place the cursor on the

parameter that needs to be set, and press the knob.

B

Change of the weld joint is confirmed, and the screen

returns to the WELDING GUIDE Screen.

•

To cancel the setting, press the CANCEL key.

2))

21

6<1

,1',9

0(18

6(/(&7

(17(5

:(/',1**8,'(

0,/'67((/

ȭ

67$1'$5'

&5$7(5),//21ZLWKSXOVH

,1,7,$/&21',7,21

:(/',1**8,'(

:(/'-2,17

㸸7-2,17

LQFK

+20(

6(/(&7

(17(5

⁐᥋⥅ᡭ

㔜ࡡ

㝮⫗

0,/'67((/

ȭ

67$1'$5'

&5$7(5),//21ZLWKSXOVH

,1,7,$/&21',7,21

6<1

:(/

',1**8,'(

:(/'-2,17

/$3-2,17

7-2,17

&$1&(/

6(/(&7

(17(5