Troubleshooting and remedial actions

▌

40

10 Troubleshooting and remedial actions

If the lineard motor or driver does not operate correctly during actuator operation, take appropriate actions by

referring to the information provided in this chapter. If the problem persists, contact your nearest Oriental Motor

office.

10-1

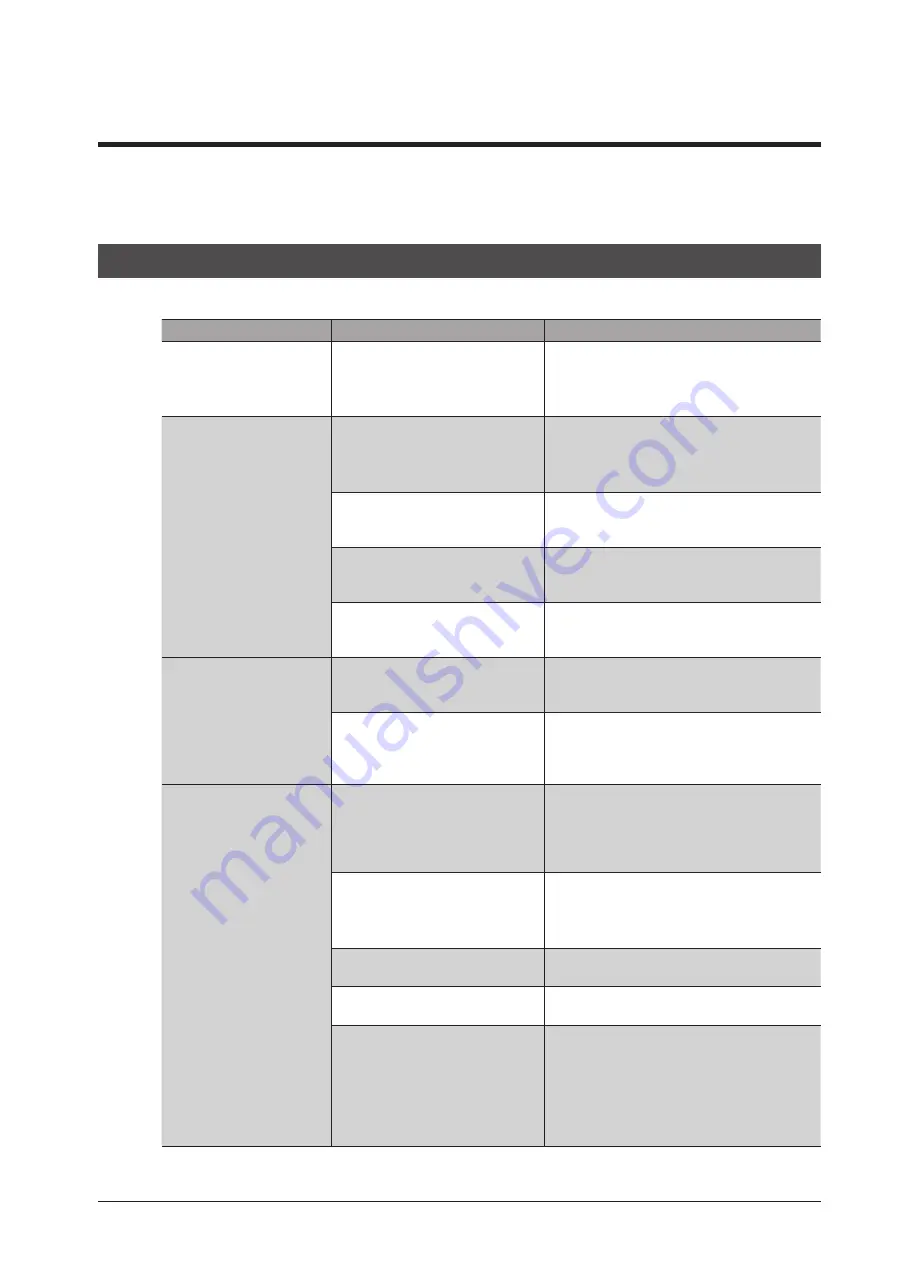

If the ALARM LED is not blinking

If the lineard motor does not operate properly even though the ALARM LED is not blinking, refer to the table below:

Phenomenon

Possible cause

Remedial action

•

The lineard motor is not

excited.

•

The rack can be turned

with the hands.

C.OFF input is ON.

Turn the C.OFF input to “OFF” and confirm that

the lineard motor is excited.

•

The rack does not move.

•

The rack cannot be moved

by hand.

Bad connection for DIR.-A or DIR.-B

input.DIR.

•

Check the connections of the controller and

driver.

•

Review the specifications (voltage and width)

for the input pulse.

In 2-pulse input mode, the DIR.-A

and DIR.-B inputs are both ON at

the same time.

Input the pulse signal either to the DIR.-A or

DIR.-B input. Make sure the terminal with no

input is set to OFF.

In 1-pulse input mode, the pulse

signal DIR.-A is connected to the

DIR.-B input.

Connect the pulse signal DIR.-A to the DIR.-A

input.

Electromagnetic brake is holding

(electromagnetic brake lineard

motor only).

Release the electromagnetic brake by turning

the power on.

The rack moves in the

direction opposite that

which is specified.

When 2-pulse input mode is

selected, the DIR.-A and DIR.-B

inputs are connected in reverse.

Connect the CW pulse input to the DIR.-A input

and CCW pulse input to DIR.-B input.

When 1-pulse input mode is

selected, the DIR.-B input is set in

reverse.

Set the DIR.-B input so that it turns ON when

the motor moves to left or downward, and

turns OFF when the motor moves to right or

upward.

Rack operation is unstable.

The current setting switch is not set

correctly.

If the set current is small, the output torque

also becomes small, resulting in unstable

operation. Reset the current setting switch on

the driver to “F” (factory setting), and check the

operation.

Bad connection of the pulse signal.

•

Check the connections of the controller and

driver.

•

Review the specifications (voltage and width)

for input pulse.

The starting pulse speed is too

high.

Set a lower starting pulse speed at which the

motor can be started reliably.

The acceleration (deceleration)

time is too short.

Set a longer acceleration (deceleration) time at

which the motor can be started stably.

Effect of noise.

Check the operation by connecting only the

lineard motor, driver and controllers needed

for operation. If effect of noise is confirmed,

take an appropriate action such as isolating

the motor from the noise source, redoing the

wiring or changing the signal cables to

shielded wires.