4-12

Sec

tio

n 4

EX

TERN

AL I/O

ZS-L

User’s Manual

Section 4

RS-232C Input/Output

Setting the Communication Specifications

Set the RS-232C communications specifications.

Match the communication specifications of the ZS-L Series to those of the external device.

FUN mode-[SYSTEM]-[COM]

For details on communication protocol, refer to the “Communication Command Reference” (provided

separately). For the Communication Command Reference, please contact your OMRON representative.

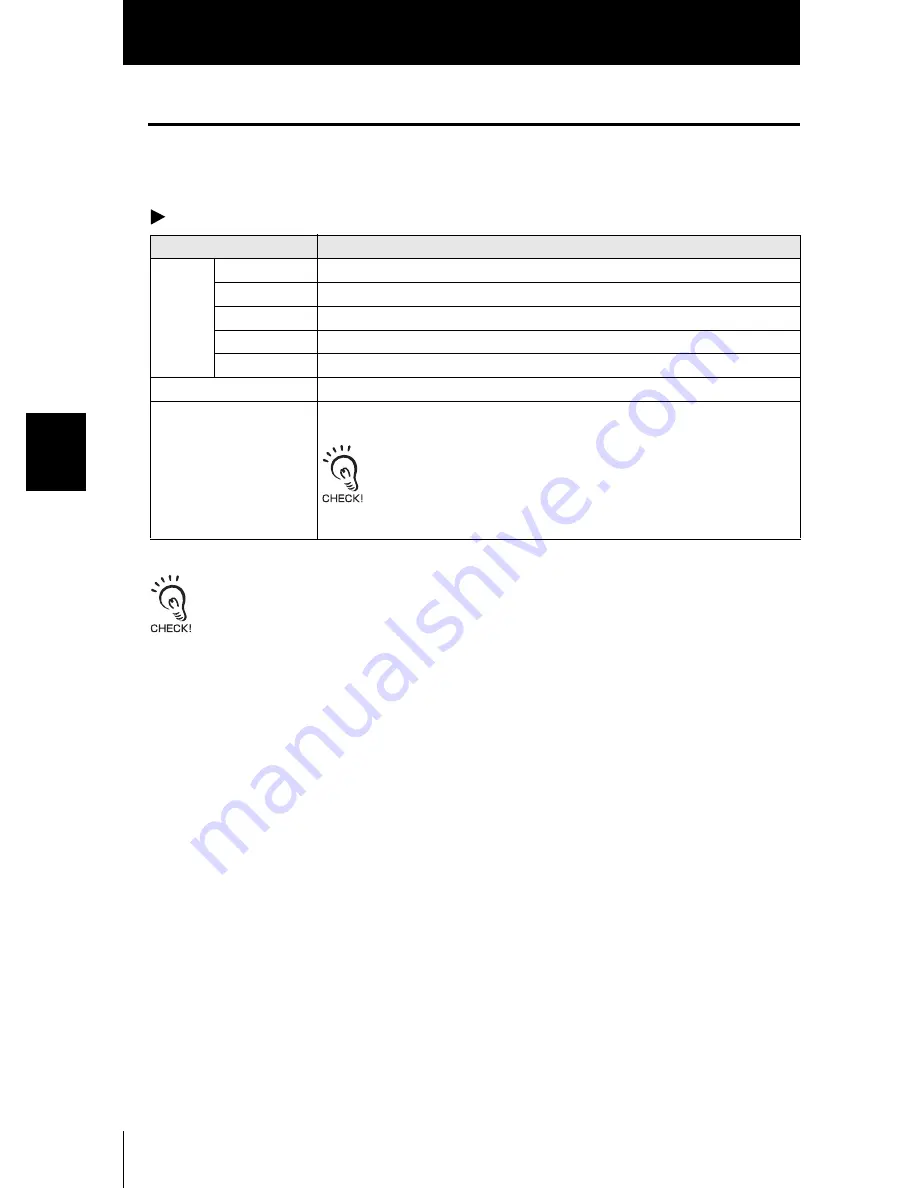

Setting

Range

RS-

232C

LENGTH

8BIT, 7BIT (default value: 8BIT)

PARITY

NON, OFF, EVEN (default value: NON)

STOP

1BIT, 2BIT (default value: 1BIT)

BAUDRAT

9600, 19200, 38400, 57600, 115200 (default value: 38400)

DELIMIT

CR, LF, CR+LF (default: CR)

MODE

CompoWay/F, non-procedural (default: CompoWay/F)

NODE (node No.)

0 to 16

The node No. refers to the connection group No. as seen from the host

device (PLC). Not only the ZS Series but other multiple devices are con-

nected to the PLC. The No. assigned to devices connected to a PLC

such as this is referred to as a node No.

Summary of Contents for ZS-L -

Page 1: ...USER S MANUAL Smart Sensor ZS L Series Ver 2 0 Cat No Z208 E1 02 ...

Page 52: ...2 24 Section 2 INSTALLATION CONNECTION ZS L User s Manual Section 2 SmartMonitor ZS ...

Page 90: ...3 38 Section 3 SETUP ZS L User s Manual Section 3 Setting the System Environment MEMO ...

Page 156: ...6 46 Section 6 APPENDIX ZS L User s Manual Section 6 INDEX ...

Page 158: ......