DMTA-10045-01EN, Rev. E, August 2016

Applications

145

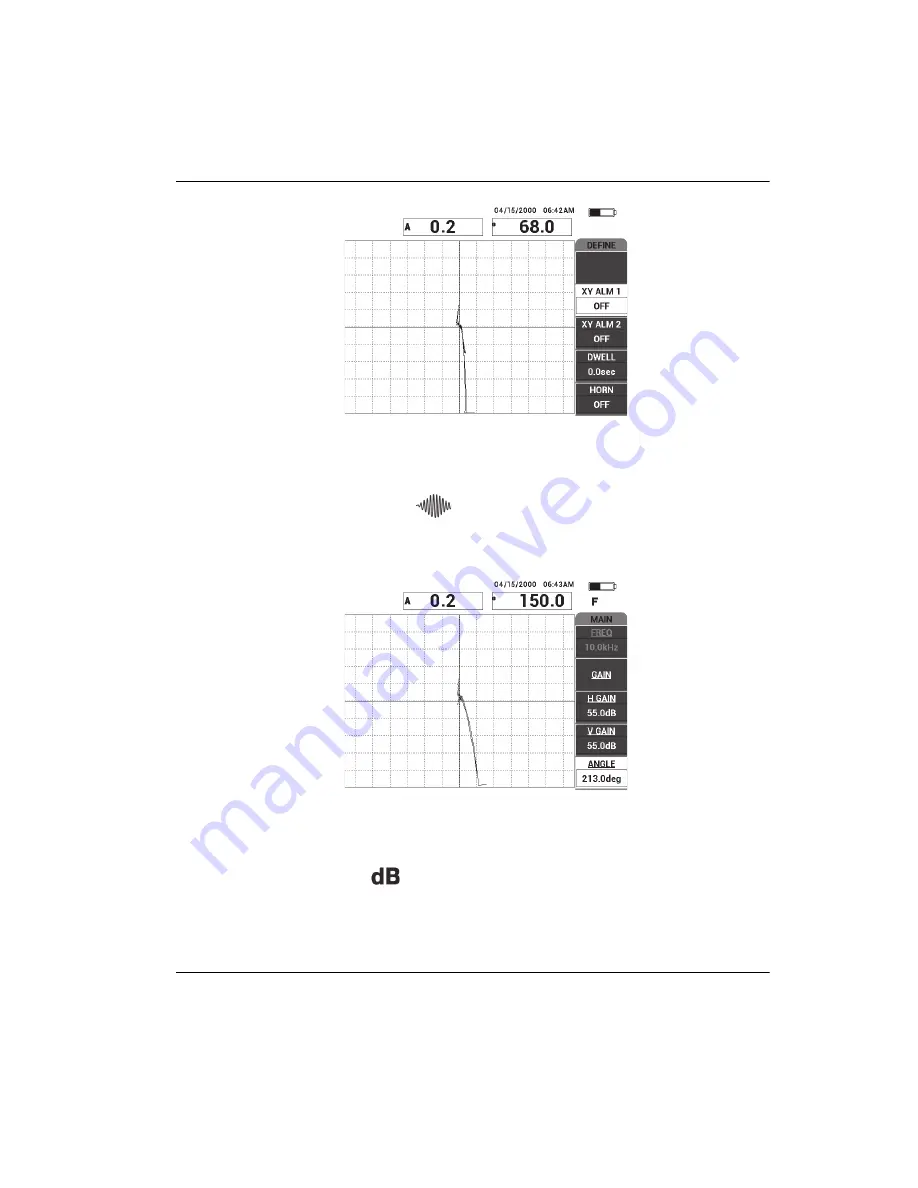

Figure 6

‑

32 The scan over the disbond and repaired area

7.

Press the MAIN menu key (

), then press

ANGLE

(E key) and adjust the

signal angle so that the disbond signal points upwards at 90° (see Figure 6-33 on

page 145).

Figure 6

‑

33 Adjusting the signal angle upwards

8.

Press the GAIN key (

), and then adjust the signal amplitude so that the

disbond signal extends to about 4 divisions away from the null position

(crosshairs) [see Figure 6-34 on page 146].

Summary of Contents for BondMaster 600

Page 8: ...DMTA 10045 01EN Rev E August 2016 Table of Contents viii ...

Page 10: ...DMTA 10045 01EN Rev E August 2016 List of Abbreviations x ...

Page 26: ...DMTA 10045 01EN Rev E August 2016 Important Information Please Read Before Use 16 ...

Page 28: ...DMTA 10045 01EN Rev E August 2016 Introduction 18 ...

Page 32: ...DMTA 10045 01EN Rev E August 2016 Chapter 1 22 ...

Page 72: ...DMTA 10045 01EN Rev E August 2016 Chapter 3 62 ...

Page 78: ...DMTA 10045 01EN Rev E August 2016 Chapter 4 68 Figure 4 2 Crosshairs and the NULL point ...

Page 130: ...DMTA 10045 01EN Rev E August 2016 Chapter 5 120 ...

Page 216: ...DMTA 10045 01EN Rev E August 2016 Chapter 7 206 ...

Page 230: ...DMTA 10045 01EN Rev E August 2016 Appendix A 220 ...

Page 234: ...DMTA 10045 01EN Rev E August 2016 Appendix B 224 ...

Page 240: ...DMTA 10045 01EN Rev E August 2016 List of Figures 230 ...

Page 242: ...DMTA 10045 01EN Rev E August 2016 List of Tables 232 ...