2KR/2KS

1-3-55

U203

Checking DP operation

Description

Simulates the original conveying operation separately in the DP.

Purpose

To check the DP operation.

Method

1. Press the start key.

2. Place an original in the DP if running this simulation with paper.

3. Select the item to be operated.

*: Dual scan DP only.

4. Press the start key. The operation starts.

5. To stop continuous operation, press the stop key.

Completion

Press the stop key. The screen for selecting a maintenance item No. is displayed.

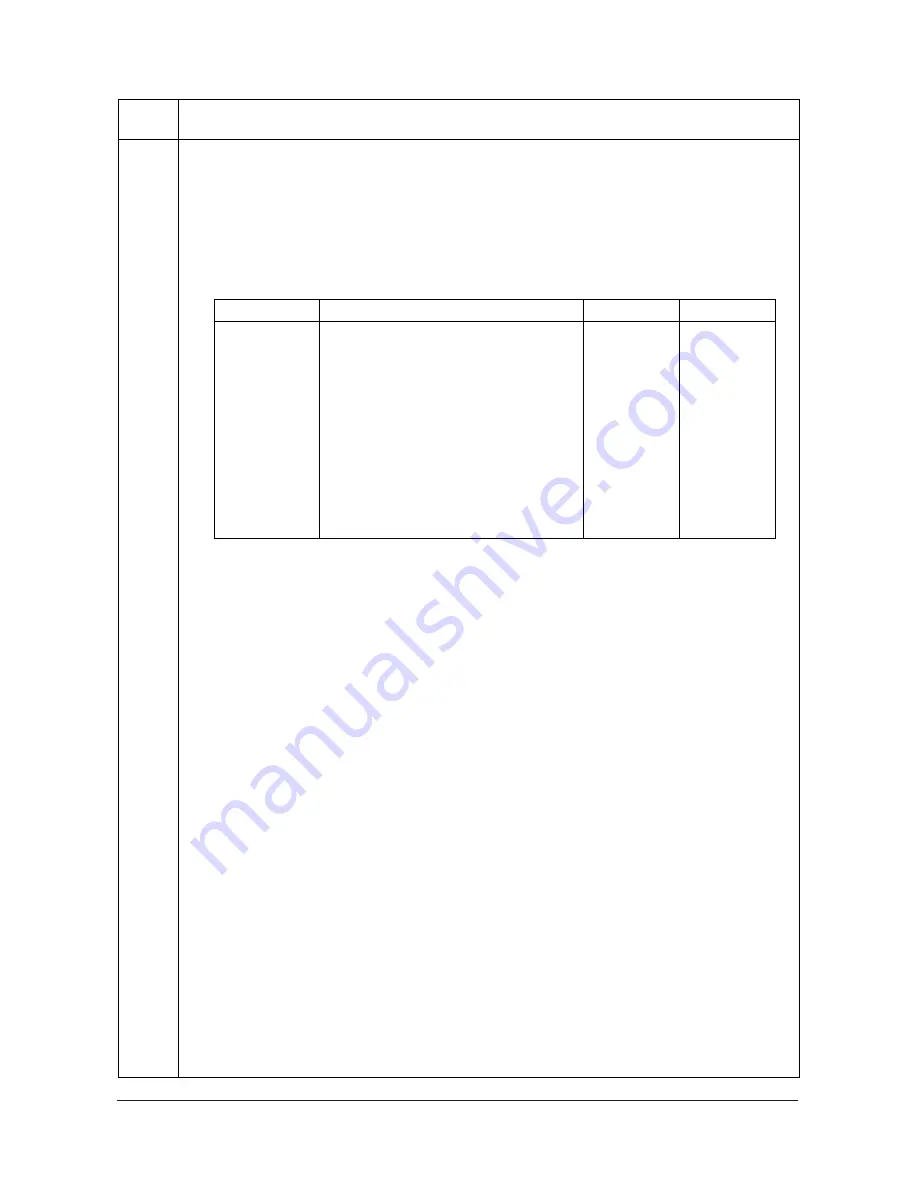

Maintenance

item No.

Description

Display

Description

Setting range

Initial setting

CCD ADP

(NON P)

Without paper, single-sided original of CCD

(continuous operation)

-

-

CCD ADP

With paper, single-sided original of CCD

-

-

CCD RADP

(NON P)

Without paper, double-sided original of CCD

(continuous operation)

-

-

CCD RADP

With paper, double-sided original of CCD

-

-

CIS RADP

(NON P)*

Without paper, double-sided original of CIS

(continuous operation)

-

-

CIS RADP*

With paper, double-sided original of CIS

-

-

SPEED

Switching between normal reading (600 dpi)

and high-speed reading

0 (Normal)/

1 (High-speed)

0

Y111960-2 Service Manual

Summary of Contents for d-Copia 5200MF

Page 1: ...d Copia 4200MF d Copia 5200MF Digital Copier SERVICE MANUAL Code Y111960 2...

Page 3: ...This page is intentionally left blank...

Page 9: ...This page is intentionally left blank...

Page 13: ...2KR 2KS This page is intentionally left blank...

Page 223: ...2KR 2KS 1 4 66 This page is intentionally left blank Service Manual Y111960 2...

Page 327: ...2KR 2KS 2 3 30 This page is intentionally left blank Service Manual Y111960 2...

Page 370: ...INSTALLATION GUIDE FOR PAPER FEEDER...

Page 378: ...INSTALLATION GUIDE FOR 3000 SHEETS PAPER FEEDER...

Page 433: ...INSTALLATION GUIDE FOR CENTER FOLDING UNIT...

Page 447: ...INSTALLATION GUIDE FOR MAILBOX...

Page 455: ...INSTALLATION GUIDE FOR HOLE PUNCH UNIT...

Page 467: ...INSTALLATION GUIDE FOR BUILT IN FINISHER...

Page 480: ...INSTALLATION GUIDE FOR JOB SEPARATOR...

Page 488: ...INSTALLATION GUIDE FOR FAX System S...

Page 502: ...UPDATINGSTATUS DATE UPDATEDPAGES PAGES CODE 04 2010 1ST EDITION 502 Y111960 2...