43856301TH Rev.3

19 /

Oki Data CONFIDENTIAL

2. Operating instructions

-+ -+ -+ -+

-+

-+

-+ -+

-+ -+

-+ -+

-

-

-

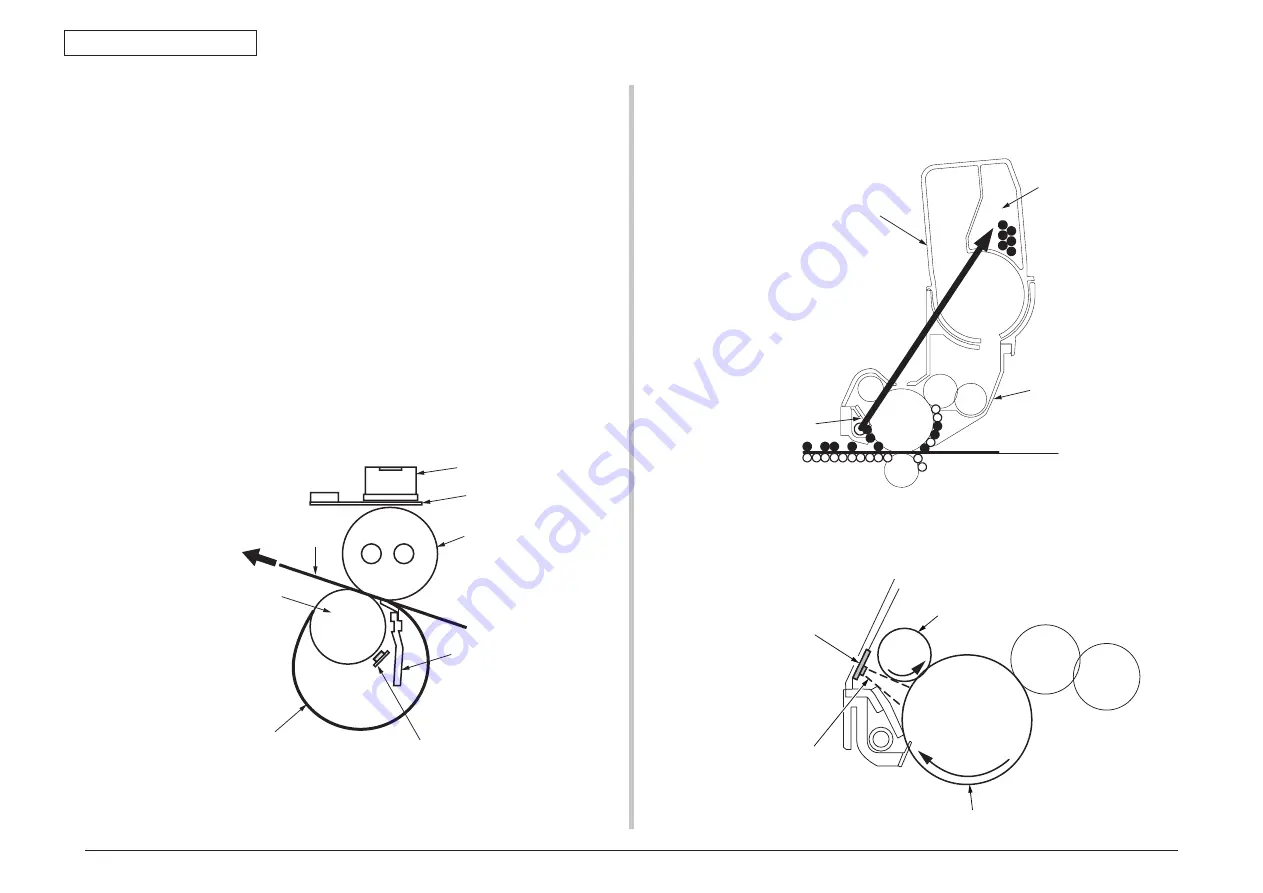

ID unit

Waste toner area

Toner cartridge

Drum cleaning blade

(6) Fusing

When the paper passes through the heat roller and backup roller unit, heat

and pressure are applied to the toner image on the paper and the toner is

fused onto the paper.

The halogen lamps of 800W and 300W are built in heat roller. The backup

roller without built-in halogen lamp is heated by the heat transmission from the

heat roller. The fusing temperature is controlled by the temperature detected by

the thermistor that is not in contacting with the surface of the heat roller. On

the other hand, the temperature detected by the thermistor rubbing the surface

of backup roller is used for controlling the fusing temperature under specified

conditions. Furthermore, a thermostat is used to limit the temperature rise, if

the temperature rise of heat roller exceeds a set point, the thermostat would

be open and the voltage supply to the heater would be cut off. The backup

roller unit is pressed on the heat roller by the spring on both sides.

(7) Drum cleaning

The Unfused toner left on the OPC drum is cleaned up by the drum cleaning

blade, and all residual toner is collected in the waste toner area of the toner

cartridge.

Heat roller

Backup roller

Pad

thermistor

thermistor

Paper

Paper feeding path

thermostat

Fuser belt

(8) Electricity removal

The electricity on the surface of the OPC drum is attenuated by irradiating the

light to the surface of the OPC drum after transfer.

Electricity-removing

light PCB

Charging roller

OPC drum

Electricity-removing

light