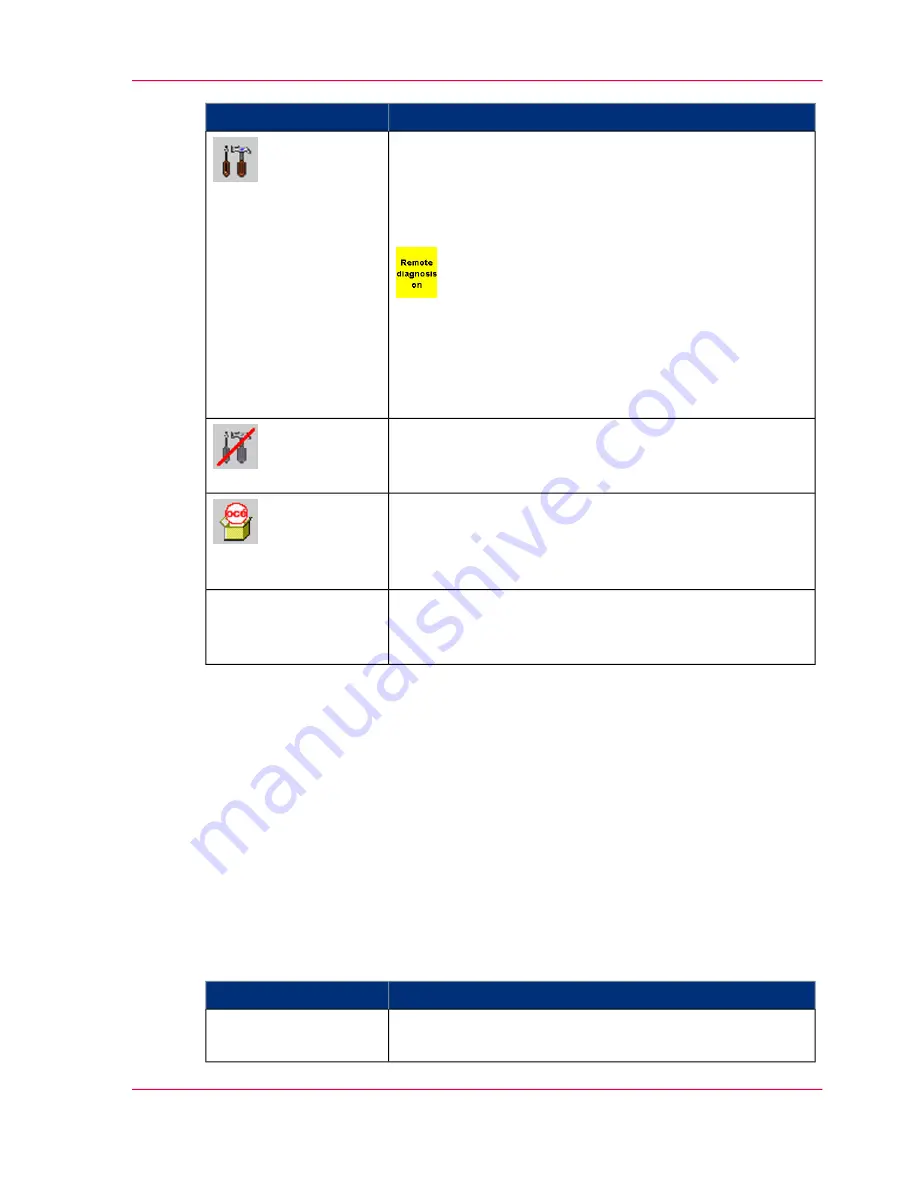

Function

Button

Indicates that remote access is activated. The Service center

can use this to perform remote diagnostics during print

operation.

Clicking the button deactivates remote access directly

without having to go through the menu.

Also indicates that remote Service diagnosis is activated. If

remote Service support was also activated, the remaining

time is displayed. One minute prior to automatic deactiva-

tion, the yellow display flashes to indicate that remote

support will shortly be deactivated.

Indicates that remote access is not activated.

Clicking the button activates remote access directly without

having to go through the menu.

Switches to the 'Consumable counter' menu.

In this menu, the current counter values and their respective

limit values are displayed for all consumables and expend-

ables of the printing system.

Switches to the 'Service ticket' menu.

This menu displays all the data required to notify the rele-

vant Service center.

'Service ticket'

Status displays

The current printer status is displayed on the centre of the toolbar. The individual status

displays have different background colors:

■

Green: The printing system is printing or is ready to print. If the printing of data in-

tegrity marks is turned off for the current configuration, an additional message to this

effect will appear.

■

Red: The printing system is stopped, operator intervention is necessary.

■

Gray: all other printer states

Status displays with green background

#

Meaning

Display

The printing system is ready to print; there are no error

messages.

'Ready'

Chapter 4 - Description of the Operator Panel

87

Buttons and Displays in the Center Area

Summary of Contents for ColorStream

Page 1: ...o More Power When Printing Oc ColorStream User Manual Continuous Printing System...

Page 10: ...10 Contents...

Page 11: ...Chapter 1 Notes on the Printing System Documentation...

Page 30: ...Chapter 1 Notes on the Printing System Documentation 30 Statutory requirements...

Page 31: ...Chapter 2 Safety...

Page 50: ...Chapter 2 Safety 50 Accident prevention regulation for replacement carts option...

Page 51: ...Chapter 3 Description of the Printing System...

Page 80: ...Chapter 3 Description of the Printing System 80 Paper specifications...

Page 81: ...Chapter 4 Description of the Opera tor Panel...

Page 105: ...Chapter 5 Working with the Operator Panel...

Page 137: ...Chapter 6 Operating the Printing System...

Page 203: ...Chapter 6 Operating the Printing System 203 5C_PrintQualityInspection 600 Test Print Job...

Page 204: ...Chapter 6 Operating the Printing System 204 5C_PrintQualityInspection 600 Test Print Job...

Page 267: ...Chapter 7 Cleaning the Printing Sys tem...

Page 310: ...Chapter 7 Cleaning the Printing System 310 Cleaning the Developer Station Shelf Optional...

Page 311: ...Chapter 8 Replacing Consumables...

Page 344: ...Chapter 8 Replacing Consumables 344 Fill in Developer...

Page 345: ...Chapter 9 Replacing Expendables...

Page 472: ...Chapter 9 Replacing Expendables 472 Replacing Expendables in Expert Mode...

Page 473: ...Chapter 10 Correcting Errors...

Page 490: ...Chapter 10 Correcting Errors 490 Correcting Print Image Errors...

Page 491: ...Appendix A Technical Data...

Page 506: ...Appendix A Technical Data 506 Ruler for Checking Paper Path Synchronization...

Page 507: ...Appendix B Comments...

Page 521: ...3...

Page 522: ...3...

Page 523: ...3...