© 2022 Genesis Attachments, LLC

Genesis GXT Mobile Shear

20

!

WARNING

Be sure hydraulic pressure is relieved before

disconnecting hydraulic fittings. Remove necessary fittings

SLOWLY.

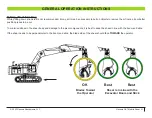

The attachment is usually shipped in an upright position. Extreme care must be used when

inverting the attachment for installation.

Follow the excavator OEM’s removal and safety instructions to remove the bucket or other stick

attachments.

Position the attachment upside down on flat, solid ground. Blocking may be required to raise the

mounting bracket into proper position.

Track the excavator to the attachment with the jaws facing the

operator. Lift the excavator stick over the attachment, carefully

positioning the stick tip connection with the attachment mounting

main pivot bore. Pin the excavator stick to the attachment.

Slowly raise the boom to lift the attachment, allowing the

cylinder pivot connection to come within range of the excavator

cylinder stroke.

Extend the excavator cylinder until the power link bore lines up

with the cylinder pivot connection. Pin the excavator cylinder to the

attachment.

Crowd and extend the attachment, checking closely to make sure

there is no interference between the bracket and hard lines. Also

check for interference between the cylinder and boom/stick.

Install excavator hydraulic hoses, supply and return, from the stick

tip to the attachment manifold blocks.

The stick and bucket circuits are oriented as to rod and bore

sides of their respective cylinders. Be sure to connect rod-to-

rod and bore-to-bore when connecting a circuit to the attachment. When these are reversed,

extra pressure is needed to open the jaw, which pulls down the engine, de-strokes the pumps,

increases jaw cycle time, creates high oil temperature and burns more fuel.

The attachment must be vertical before putting oil into it or an air lock in the regen valve may

prevent the jaw from opening.

SHEAR INSTALLATION

!

WARNING

Removing any connecting pin may be hazardous. To remove

a connecting pin, position the attachment on the ground and

properly support.

Particles may fly when a pin is struck. Use a drift pin or mallet

when striking pins. Keep all personnel at a safe distance.