© 2022 Genesis Attachments, LLC

Genesis GXT Mobile Shear 37

Four-Hour Checklist

Mid-shift, perform a brief visual check for hydraulic leaks, blade damage, and loose or missing

bolts. A more thorough inspection, to be performed at the end of each shift, is described below on

the eight-hour checklist.

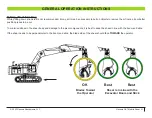

Grease:

• Shear cylinder - end of pin

• Shear cylinder rod

•

AutoGuide at fitting and smear grease on contact surface of upper jaw

• Main shaft/pivot, both sides

Grease all locations until grease extrusion is visible with jaw open and closed.

Eight-Hour Checklist

Inspect:

• Bolts - check for loose bolts, replace if damaged

• Fittings and hoses for damage or leaks

• Bracket pivot for wear and pin retainers

• Cylinder pivot for wear and pin retainers

• Entire shear for cracks (visual check)

Grease:

• Bracket pivot

• Bracket cylinder

• Bearing slewing (four locations)

• All points listed in 4-hour checklist

Grease all locations until grease extrusion is visible.

Jaws and Blades:

• Check blade gaps*

• Check blade edge radiuses*

• Check for loose or damaged bolts, re-torquing loose bolts when cool

• Check AutoGuide and shim if needed

• Build-up and hard-surface as required

•

Grind off any rolled-over or mushroomed blade edges

• Shear Jaw Armor

®

- build-up and hard-surface as needed

* See Blade Maintenance information in this manual regarding maximum gap and radius for

your specific shear model. Blade gaps should be checked and maintenance performed when

the shear has cooled to ambient temperature.

MAINTENANCE SCHEDULE