© 2022 Genesis Attachments, LLC

Genesis GXT Mobile Shear 21

ROTATOR INSTALLATION

The rotator requires a 1/2” minimum case-drain line with

a minimum working pressure rating of 250 PSI.

Run the

case-drain line from the rotation head of the shear to

a dedicated filter on the excavator, plumbed directly

into the main section of the hydraulic tank. Do not

plumb to the return side of the tank.

The maximum case-drain pressure measured at the motor

while attempting to rotate the shear stalled on the ground

is 40 PSI for an axial piston motor. Gerotor type motors

may or may not require a case drain. If 3 O-ring face seal

bulkheads are present on your sub-head, a case drain is

required. If you are unsure of your motor type or if a case

drain is required, contact the Genesis Parts or Service

Departments with the serial number of your shear. Case-

drain pressures will rise during cold weather operation.

Use the correct fittings. Secure the case-drain line to the excavator stick.

Do not plumb the case-drain into the main return

system or into any other existing case drain or return

circuit. Plumb only to the hydraulic tank.

NOTICE

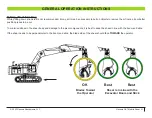

GXT 115-335 Rotation Motor

The gerotor motor is a direct drive motor.

GXT 445 and Larger Rotation Motors

A piston motor is now the standard motor for models

GXT 445 and larger. Piston motors are used in overhead

demolition and material handling applications that

require fine control and solid load holding capabilities.

These motors are more expensive and require

additional plumbing but have advantages in load-holding

applications.

On early GXT 445 and larger models, a gear motor

was the standard motor. This motor is for processing

applications where the shear is usually working vertically,

such as in scrap yards and on demolition sites where

material is on the ground. These motors may slowly drift

or rotate in material handling applications.

-6 Flatface

Case drain

Gear Motor

Piston Motor

Gerotor Motor