© 2022 Genesis Attachments, LLC

Genesis GXT Mobile Shear 45

GUIDE BLADES

After adjusting the AutoGuide, check guide blade tolerances.

When necessary, shim the guide blade to keep the gap within the

specifications listed in the Blade Gap table below.

Rotate the guide blades when worn to a 1/8” (3 mm) radius.

Replace a guide blade when more than 0.075” (2 mm) of shims

are required to keep the blade gap within tolerance.

Dual guide blades, one on either side of the lower jaw, allow for

a wider tip-to-guide blade gap than is used between the main

cutting blades. Friction and heat buildup cause piercing blades

to expand, reducing clearance, possibly to the point of blade

interference. Therefore, in most applications, it is beneficial to

maintain a wider gap at the guide blades.

Shimming

Slowly close the jaw so the upper piercing blades begin to

bypass the guide blades. Stop the jaw and check the gap

between the guide blades and piercing blades. Cycle the jaws

slowly, stopping at several points along the piercing blades to

check the gap each time.

Shim the guide blades as needed to keep the gap within the

tolerances listed in the Blade Gaps table.

To install shims, loosen blade bolts and slide shims between the

guide blade and adjustment plate. Re-torque bolts and recheck

the gap.

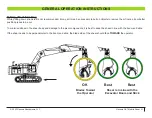

Mach Guide Blade Adjust Plate

Guide Blade to Piercing Blades Gap

Model

Minimum

Maximum

115

0.010”

0.020”

225

0.010”

0.020”

335

0.010”

0.020”

445

0.010”

0.020”

555

0.010”

0.020”

665

0.015”

0.025”

775

0.015”

0.025”

995

0.020”

0.030”

1555

0.020”

0.030”

2055

0.025”

0.035”

2555

0.025”

0.035”

Blade Gap Location

Shims

Guide Blade