267

Service Manual – SW5500, FLOORTEC R 985

52 - Hopper System

Functional Description

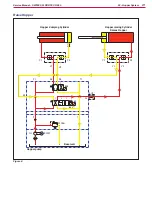

The hopper lifting and dumping system is operated by two hydraulic cylinders driven by an hopper pump

(M3) with integrated hydraulic unit

The hopper pump (M3) is powered by the Main Machine Controller (EB1)

Activation of various solenoid valves allows the hopper pump (M3) to move the two hydraulic cylinders in the

required direction, according to the following table:

ACTIVATION OF OUTPUTS FOR HOPPER MOVEMENTS

Command

Button

HOPPER PUMP

(M3)

RAISING VALVE

(EV1)

LOWERING VALVE

(EV2)

DUMPING VALVE

(EV3)

Raise

X

X

Lower

X

X

Dumping

X

X

Return to horizontal

position

X

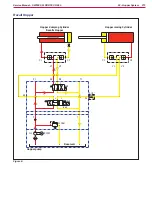

When the hopper comes out of its rest position, the hopper closed sensor (S1, light sensor on) provides its

signal to the Main Machine Controller (EB1) in order to obtain the following automatic functions: reduction

of machine maximum speed, sounding of the buzzer (BZ, on the Main Machine Controller), displaying the

hopper lifting icon on the display, switching off the vacuum system motor (M1) and the broom motors (M4,

M5, M6)

When the hopper reaches a height sufficient to activate the hopper lifted sensor (S2, light sensor on),

rotation of the hopper can be activated with the dumping button to empty the hopper, and then the return

button can be used to return the hopper to the horizontal position

When the hopper dumping sensor (S3) detects that the hopper is not in the horizontal position, activation of

the hopper lowering button is disabled

When the hopper is not in the horizontal position, the hopper dumping sensor (S3, light sensor off) disables

the activation of the hopper lowering button

SENSORS HOPPER WORK

Sensor

Light built-in

sensor

Sensor

output

Effect

S1

OFF

0V

-

ON

24V

- Low gear speed - No vacuum - No brooms rotation - Buzzer ON

S2

OFF

0V

- No hopper dumping (inhibited dumping button)

ON

24V

-

S3

OFF

0V

- No hopper lowering (inhibited lower button)

ON

24V

-