101

Service Manual – SW5500, FLOORTEC R 985

20 - Wheel System, Traction

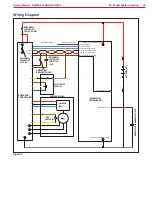

Driving Wheel Motor Current Draw Check (continues)

8 For safety purposes, to prevent accidental lowering of the machine, apply two suitable spacers under the

right (I) and left (J) side brackets

9 Working on the drive board (M), apply the ammeter clamp (K) to the drive motor electrical cable (L)

10 Start the machine with the ignition key

11 With the help of an assistant, carefully seat on the driver’s seat to activate the microswitch, then turn

on the drive system at the maximum speed and check that the driving wheel amperage is within 15 and

25A at 24Vac

Stop the drive system

Turn the ignition key to “0”

Remove the ammeter clamp (K)

If the amperage is higher, perform the following procedures to detect and correct it:

◦

Check that there is no dust or debris (ropes, cables, etc ) on the driving wheel, that can prevent it

from turning

◦

If necessary, disassemble the drive system motor (see

in the relevant paragraph), and

check the condition of all its components

If the above-mentioned procedures do not lead to a correct amperage, the drive system motor must be

replaced (see

Reassembly

12 Perform steps 3 to 7 in the reverse order

Figure 6:

I

K

L

J

M