127

Service Manual – SW5500, FLOORTEC R 985

24 - Electrical System

Functional Description - Diesel, LPG Version

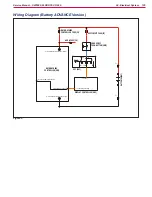

The electrical system of Diesel and LPG versions is

substantially equal to that of the battery versions,

the difference is that the 24V battery pack is

replaced by one with lower capacity (2 x 12Vdc

starter batteries) kept charged by a three-phase

alternator and a three-phase power bridge rectifier.

Between the output of the bridge rectifier and the

battery pack is the relay (ES10) contact and the

charging system fuse (F4)

The relay (ES10) separates the output of the rectifier

from the batteries when the engine is running with

all services switched off for over 10 sec or when the

battery voltage reaches the limit value of 32V

The Diesed and LPG engine are started via the

starter motor (MST) when the key switch (KEY) is

turned to position II

The Main Machine Controller (EB1) continuously

checks the alternator output voltage (D1, alternator

input J1 14) to determine if the engine is on or off

With off engine the sweeping and vacuum functions

are inhibited

Only on LPG version

The electronic engine speed regulation system

(EB6) reduces the engine speed from 3,000 rpm to

2,300 rpm when the relay (ES10) disconnects the

rectifier output from the batteries. Commands to

the electronic system of the engine are provided

by opening the contacts of the relay (ES4) which is

driven by the Main Machine Controller (EB1)

(NB: the reduction in engine speed may not be

immediate as the engine electronic system takes

other parameters into account such as engine

temperature and carburation when deciding

whether to reduce the set speed or not, even if the

corresponding input is open)

The engine fuel supply system is fitted with a safety

solenoid valve (EV4) which allows LPG to flow to the

engine only when powered

The solenoid valve (EV4) is powered when the key

switch (KEY) is in position II, and for the first 10

seconds of operation when it is in position I After

these 10 seconds have passed, if the engine has

not been started power is cut to the solenoid valve;

otherwise, it remains active as long as the engine is

running

The solenoid valve is managed by the Main Machine

Controller (EB1), via output J2 6 The Main Machine

Controller (EB1) checks the status of the engine

via input J1 14 connected to the secondary bridge

rectifier (D1).

The entire electrical and electronic system of the

engine (including the starter motor) runs on 12V,

taken from one of the machine’s two 12V batteries

The engine is equipped with an internal alternator

which restores the energy taken from the 12V

battery on starting

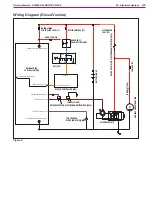

Only on Diesel version

The engine fuel supply system is fitted with a safety

solenoid valve (EV4) and a fuel pump (P2) which

allow diesel to flow to the engine only when powered.

The solenoid valve (EV4) and the pump (P2) are

powered when the key switch (KEY) is in position II,

and for the first 10 seconds of operation when it is

in position I After these 10 seconds have passed, if

the engine has not been started power is cut to them;

otherwise, they remain active as long as the engine

is running

The solenoid valve and the pump are managed by

the Main Machine Controller (EB1) via output J2 6

which activates relay (ES7) The Main Machine

Controller (EB1) checks the status of the engine

via input J1 14 connected to the secondary bridge

rectifier (D1).

The solenoid valve (EV4) and the pump (P2) run at

approx 12V, reducing the battery voltage (24V) via

the resistor (R4)