16

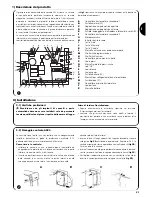

6) Servicing

The control unit is an electronic component and therefore needs no particular maintenance; however, the board and the relative connected devices

should be periodically checked (at least every 6 months) by carrying out the whole testing procedure (see Chap. 4).

In order to plan the maintenance programme for the whole system, a manoeuvre counter has been fitted to the control unit which increases its val-

ue after every opening manoeuvre. The Maintenance (MAN) led flashes to signal this increase. The value of the manoeuvre counter is constantly

compared with an alarm threshold (programmable by the fitter) and the warning threshold (automatically set to the alarm threshold less about 6%).

When the number of manoeuvres performed exceeds the warning threshold, the maintenance led only flashes during manoeuvres, while if the alarm

threshold is exceeded it continues to flash (with the motor stopped and moving) in order to signal that maintenance must be performed.

The alarm threshold can be programmed from a minimum value of 200 to a maximum value of 50800 manoeuvres in multiples of 200.

Tabella “I”

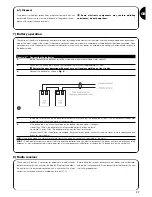

Programming the alarm threshold

1.

Set the dip switches as shown

2.

Divide the number of manoeuvres to programme by 100 and then by 2

Example: number of manoeuvres

3.

Consult the table to find the combination of Dip Switches giving the same total value

to programme: 30,000

as the above number and move the relative Dip Switches to On.

Results after dividing: 150

150 = 128 + 16 + 4 + 2,

Dip Switches 5 , 8, 3 and 2 to On

4.

Perform the “Memorisation procedure” (see paragraph 3.3)

After programming the alarm threshold, visualise it in order to check the operation was performed correctly.

Table “L”

Visualising the alarm threshold

1.

Set the dip switches as shown:

2.

Move the Dip Switch 1 to On (2,3,4 and 5 to Off), count the number of times the ok led flashes and write the number on a piece

of paper (if it is 10, write 0)

3.

Repeat the operation with Dip Switches 2, 3, 4 and 5

4.

Reconstruct the number of manoeuvres as shown in one of the following two examples

Use the same procedure to visualise the number of manoeuvres performed;

Tabella “M” To visualise the number of manoeuvres performed

1.

Set the dip switches as shown:

2.

Count the number of times the “OK” led flashes with Dip Switches 1, 2, 3, 4 and 5 as shown in examples 1 or 2.

N.B.

whenever the warning threshold is programmed the number of manoeuvres performed is automatically cancelled.

1 2 3 4 5 6 7 8 9 10

11 12

1 2 3 4 5 6 7 8 9 10

11 12

1 2 3 4 5 6 7 8 9 10

11 12

1 2 3 4 5 6 7 8 9 10

11 12

Dip-switch

Sw1

Sw2

Sw3

Sw4

Sw5

Sw6

Sw7

Sw8

Value

1

2

4

8

16

32

64

128

Dip Switch

arrangement

1 2 3 4 5 6

Number of

manoeuvres

1 2 3 4 5 6

1 2 3 4 5 6

1 2 3 4 5 6

1 2 3 4 5 6

Example

n° 1

Number of times

“OK” led flashes

10

1

1

4

2

10

10

10

4

7

1.204

Example

n° 2

Number of times

“OK” led flashes

14.007

Summary of Contents for Mindy A924

Page 2: ...mindy...

Page 3: ...A924...

Page 19: ...19 Nice reserves the right to modify the products whenever it sees fit...