13

Appendix

64

V2.20161017

30252060-02-EN

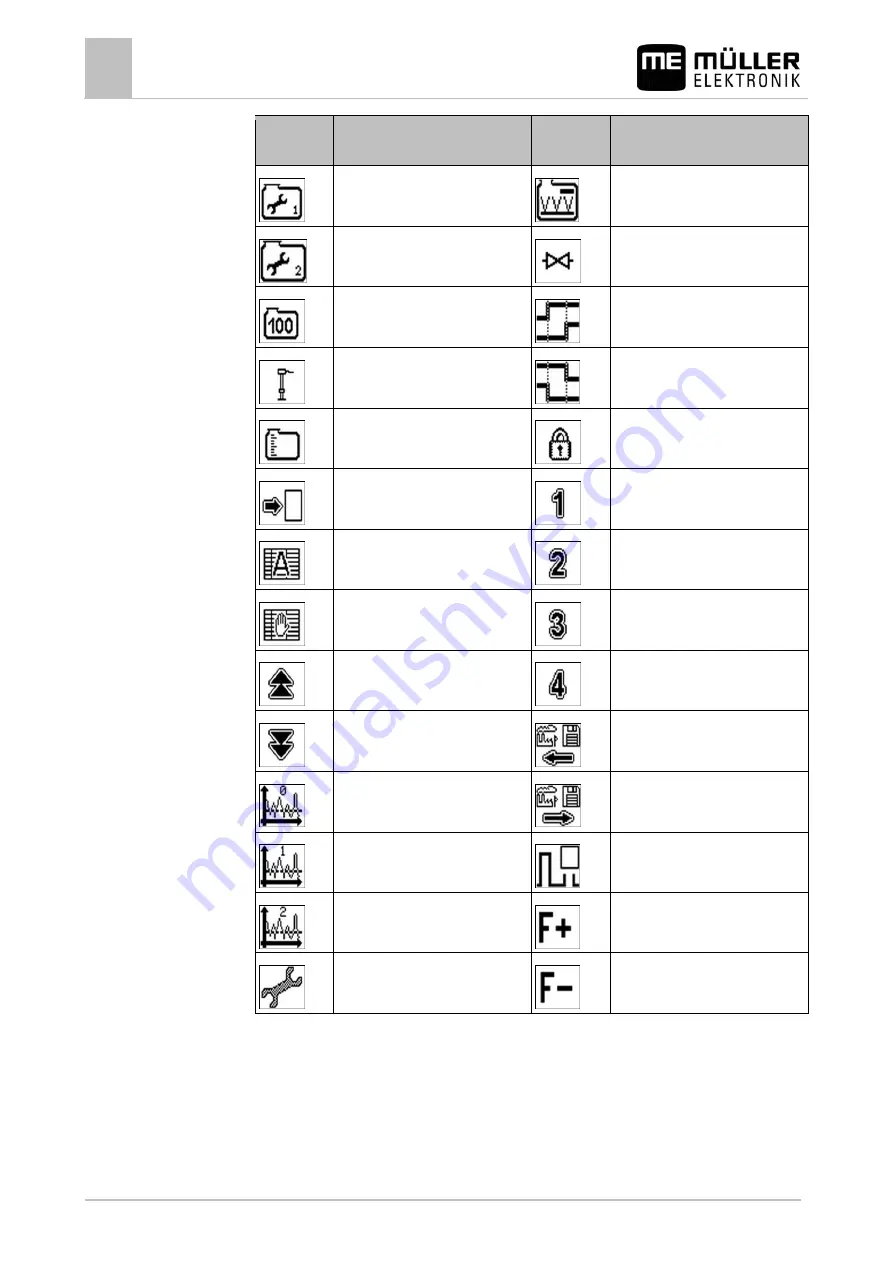

Function

icon

Function

Function

icon

Function

Carry out 100 litre calibration [

Carry out basic initialisation [

Calibrate tank or select tank type [

Open locked area

Enter a figure in the protected

area

Enter a figure in the protected

area

Enter calibration values manually [

Enter a figure in the protected

area

Scroll up through measured

values

Enter a figure in the protected

area

Scroll down through measured

values

Set sensor sensitivity to high [

Set sensor sensitivity to normal [

Set sensor sensitivity to low [

View configuration of external

devices [

Summary of Contents for TANK-Control II

Page 65: ...w w w R O L T R O N I K p l...

Page 66: ...w w w R O L T R O N I K p l...