Temposonics

®

R-Series

V

PROFINET IO RT & IRT

Operation Manual

I 35 I

•

Maximum master sign-of-life failures:

Specifies the number of allowed failures of the masters sign-of-

life. This parameter is only supported in compatibility mode V3.1.

If the maximum number of permissible errors is exceeded, the

position sensor sends a sign of life error in G1_XIST2.

• Velocity unit

3

:

Specifies the coding of the velocity units used to configure the

signals NIST_A and NIST_B (Fig. 5959).

Velocity measuring units

Value

Steps/s

0

Steps/100 ms

1

Steps/10 ms

2

Fig. 59: Velocity units

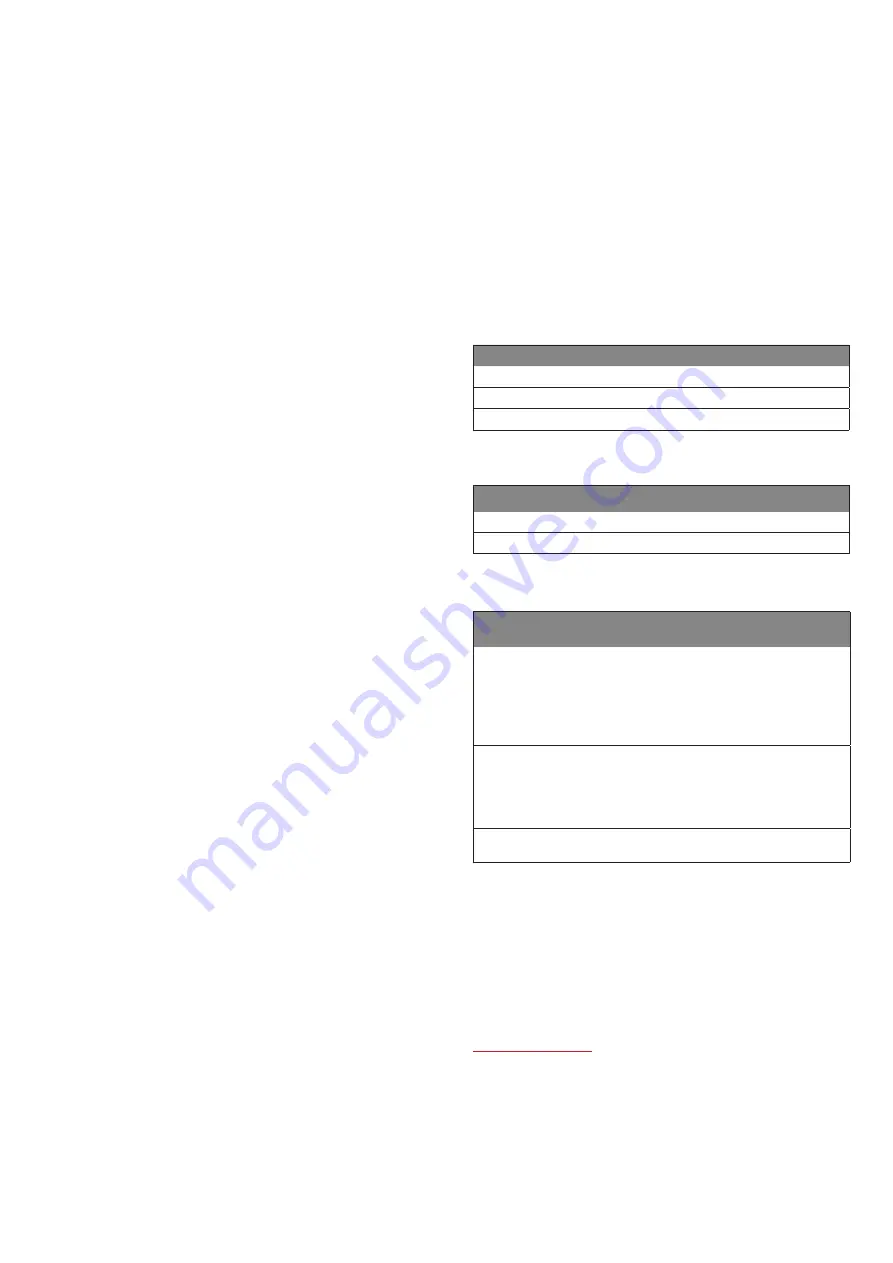

Attribute

Meaning

Value

Enable

Compatibility with encoder profile V3.1

0

Disable

No backward compatibility (default)

1

Fig. 60: Compatibilty mode

Function

Compatibility mode

enabled (= 0)

Compatibility mode

disabled (= 1)

Control by

PLC

(STW2_ENC)

Ignored, the control word

(G1_STW) and the set

point values are always

valid. Control requested

(ZSW2_ENC) is not

supported and is set to 0.

Supported

User

parameter

alarm

channel

control

Supported

Not supported, the

application alarm channel

is active and controlled by

a PROFIdrive parameter.

P965 Profile

Version

31 (V3.1)

42 (V4.2)

Fig. 61: Function

3/

A “step” corresponds to the selected resolution

In addition to the manufacturer-specific parameters, there are the

following standard parameters according to the encoder profile:

•

Code sequence:

Specifies the measurement direction for position measurement

• CW (clockwise) = forward (values increasing from sensor

electronics housing to rod end/profile end)

(default value)

• CCW (counter clockwise) = reverse (values decreasing from

sensor electronics housing to rod end/profile end)

•

Class 4 functionality:

Activating/deactivating the following parameters: Code sequence,

scaling function, measuring step, total measuring range, velocity

unit and G1_XIST1 preset control. With “Class 4 functionality”

de-activated, the sensor measures with a resolution of 1 μm.

Any configured “Preset” is not taken into account and the

measuring direction is forward. If the parameter “G1_XIST1

preset control” is activated this will affect G1_XIST1, G1_XIST2

and G1_XIST3.

•

G1_XIST1 preset control (preset affects XIST1):

Specifies the effect of a preset on G1_XIST1. This parameter

is without function if the parameter Class 4 funtionality is

deactivated. If Class 4 functionality is activated and G1_XIST1

preset control is disabled, the position value in G1_XIST1 will not

be affected by a preset. Should be selected, if the preset should

have an impact not only on G1_XIST2 and G1_XIST3, but also on

G1_XIST1.

•

Scaling function control:

Activating/deactivating the scaling function. The “Scaling

function”- parameter can be used to change the encoder

resolution. Note that the “Scaling function” parameters can be

activated only, if “Class 4 functionality” and “Scaling function

control” are activated. Otherwise, the scaling function is disabled

and the resolution is 1 μm.

•

Alarm channel control:

Activating/deactivating the alarm channel. This parameter is used

to limit the amount of data sent. This parameter is only supported

in compatibility mode and can be deactivated only in compatibility

mode V3.1.

•

Compatibility mode V3.1:

Activating/deactivating the compatibility mode. This parameter

indicates, if the sensor should run in a mode compatible with

encoder profile 3.1. The functions which are affected when this

parameter is activated are listed in Fig. 611.

•

Measurement step:

Position measurement resolution 0.5, 1, 2, 5, 10, 50, 100 μm,

provided that the “Scaling function” is activated.

•

Measurement range:

Limits the measuring range to the number of measurement steps,

provided that the “Scaling function” is activated.

For more information about the standard parameters and functions

according to the encoder profile V4.2 please refer to the document

"Profile Drive Technology Encoder-Profile (Version 4.2)" from

PROFIBUS Nutzerorganisation e.V..

The operation manual and the GSD file for the R-Series

V

PROFINET

with encoder profile 4.1 (Profinet firmware < 2.2) can be found at

www.mtssensors.com

under "Legacy Products".