English

Operating manual for snow thrower

10

Maintenance tasks

`~ìíáçå

mçëëáÄáäáíó=çÑ=ÇçáåÖ=Ç~ã~ÖÉ=

íç=íÜÉ=ã~ÅÜáåÉ

tÜÉå=êÉéä~ÅáåÖ=é~êíë=çÑ=íÜÉ=ã~ÅÜáåÉ=

ìëÉ=çåäó=çêáÖáå~ä=ëé~êÉ=é~êíëK

`~ìíáçå

båÖáåÉ=çáä=áë=Ü~ò~êÇçìë=

íç=íÜÉ=ÉåîáêçåãÉåí

^ÑíÉê=ÅÜ~åÖáåÖ=íÜÉ=çáäI=í~âÉ=íÜÉ=

ï~ëíÉ=çáä=íç=~=ï~ëíÉ=çáä=ÅçääÉÅíáåÖ=

éçáåí=çê=íç=~=ï~ëíÉ=Çáëéçë~ä=

Åçãé~åóK

Clean the machine

^ííÉåíáçå

aç=åçí=ÅäÉ~å=íÜÉ=ìåáí=ïáíÜ=~=ÜáÖÜJ

éêÉëëìêÉ=ÅäÉ~åÉê

Park the machine on a firm, even

and horizontal piece of ground.

Remove any dirt sticking to it.

Clean the machine by pouring

water through the throw-out

chute, leave it to dry.

Clean engine with a cloth and

brush.

Lubrication

Lubricate all rotating and mobile

parts with a light oil.

Adjust tyre pressure

^ííÉåíáçå

oáëâ=çÑ=Éñéäçëáçå>

kÉîÉê=ÉñÅÉÉÇ=íÜÉ=ã~ñáãìã=íóêÉ=

éêÉëëìêÉ=çÑ=NKQ=Ä~êLOM=éëáK

Recommended tyre pressure:

1.0 bar.

Checking and setting

the worm drive clutch

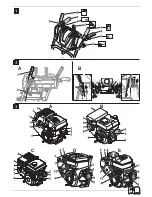

Fig. 2A

Release clutch lever (1).

There must be no slackness

on the coupling cable (2) but

it must not be taut either.

Adjust if necessary (see “Making

adjustments to the coupling

cable”).

It must be possible to depress

the clutch lever (1) all the way.

If it does not, the coupling cable

is tightened too firmly and must

be slackened (see “Making adjust-

ments to the coupling cable”).

Additional check: (see “Working with

the unit/ operating sequence”)

When the motor is running

(“

”), switch on the auger drive

for 10 seconds.

Release the clutch lever, the

snow-throwing auger must

no longer rotate.

Check and set clutch

for travel drive

Fig. 1

(Machines with caterpillar drive)

Set setting lever (Fig. 4, Pos. 1)

to position IV (Transport).

Set shift lever (6) to the fastest

forward gear (highest figure).

Having released the coupling lever (2),

push the machine forwards.

While pushing, move the shift

lever (6) to fastest reverse gear

“R

/R2” and then to fastest

forward gear.

If some resistance is felt while

you are pushing the machine

or changing gear, you need

to slacken the coupling cable

(see “Making adjustments to the

coupling cable”).

While you are pushing the machine,

press coupling lever (2).

The wheels/caterpillar tracks must

become blocked. If not, tighten the

coupling cable a little (see “Making

adjustments to the coupling cable”).

If the setting is still not correct,

repeat the process.

Making adjustments

to the coupling cable

Fig. 2B

For clutch cables with adjusting

plate for wheel drive (3) or for

worm drive (4):

– Tension: Loosen screw (A) depen-

ding on the adjusting plate, push

down adjusting plate and retigh-

ten screw (A).

– Slacken: Loosen screw (A) depen-

ding on adjusting plate, push

up adjusting plate and retighten

screw (A).

Adjust shift lever

Units with shift linkage (1)

Fig. 9

Remove spring clip (4) and washer

(5), extract spindle nut (6) from

the hole (7).

Press gearshift arm (2) downwards,

set shift lever (3) to gear “6”.

Rotate spindle nut (6) in such

a way that the pin can be put

into the same hole (7).

Secure spindle nut with washer

and spring clip.

Note

This setting is not required unless

the quickest gear (forwards or

backwards) cannot be engaged.

Adjusting the caterpillar

track (Machines with

caterpillar drive)

Note

Have this work carried out only

by a specialist workshop.

Fig. 5

The caterpillar track (1) has been set

correctly when it can be depressed

manually by 9–10 mm (applying

a pressure of 6.4–9 kg).

If it can be forced down by a greater

or lesser amount, it must be

adjusted:

Position unit on a secure and level

surface.

Loosen nut (3) on each caterpillar

side.

Rotate nut (2) until the caterpillar

track has the correct tension:

– To tighten, rotate in clockwise

direction.

– To slacken, rotate in anti-

clockwise direction.

Retighten nut (3) on each cater-

pillar side.

Note

Adjust both caterpillar tracks evenly

so that the rear axle (4) is parallel to

the front axle. In doing so, the length

of the thread (x) on both adjusting

screws should be the same.

Summary of Contents for Cub Cadet E 22

Page 1: ...769 20912B MTD Products Aktiengesellschaft Saarbrücken Germany E 22 ...

Page 2: ......

Page 3: ...E D C A B A B 1 2 A A ...

Page 4: ...9 10mm max ...

Page 5: ...3 8 2 6 1 7 5 4 1 ...

Page 6: ...Typ 1 Typ 2 Typ 3 109 111 113 ...

Page 7: ...4 13 24 34 44 54 63 72 81 90 99 ...

Page 113: ...1 66 Typ 5 Typ 1 109 ...

Page 114: ...A B Typ 5 Typ 1 110 ...

Page 115: ...1 66 Typ 5 Typ 2 111 ...

Page 116: ...A B Typ 5 Typ 2 112 ...

Page 117: ...1 66 Typ 3 113 ...

Page 118: ...A B Typ 5 Typ 3 114 ...