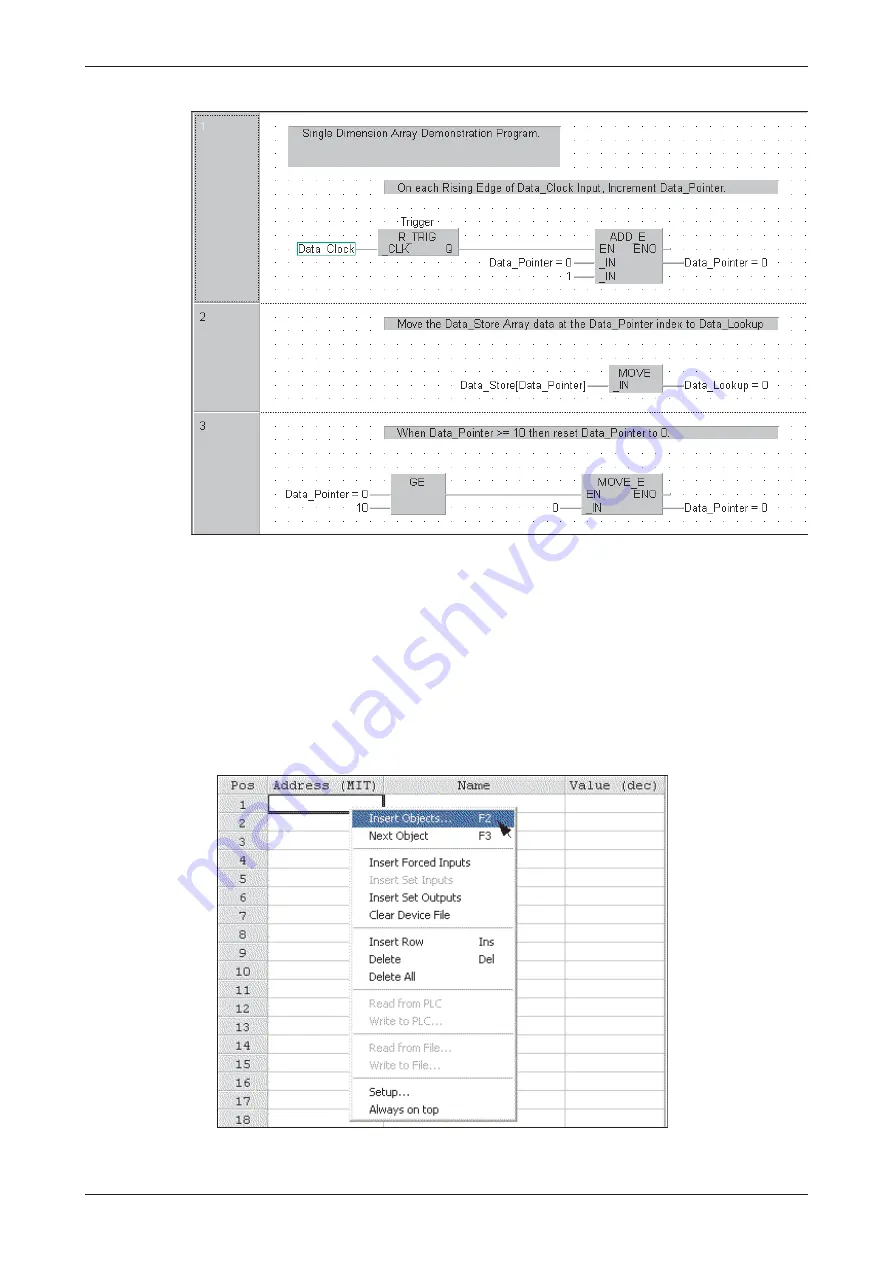

Before the program is able to function as intended it is necessary to input data into the physical

MELSEC addresses occupied by the array variables. There are two ways in which this may be

achieved:

쎲

Use the

Device Edit

feature from the

Debug

menu as previously described, using

Insert

Devices

in the range D100 to D109, and enter any 10 random integer values between

-32768 to +32767 and write them to the PLC.

쎲

Open the

Entry Data Monitor

feature from the

Online

menu.

–

Right Click on the

Address

or

Name

column headers and select

Insert Objects

from

the menu list as shown:

Arrays

Array Example: Single Dimension Array

Training Manual GX IEC Developer

11 - 5

Summary of Contents for FX2N-32CAN

Page 1: ...MITSUBISHI ELECTRIC FACTORY AUTOMATION Programmable Logic Controllers GX IEC Developer ...

Page 2: ......

Page 4: ......

Page 6: ......

Page 10: ...IV MITSUBISHI ELECTRIC ...

Page 18: ...Modular PLC Training Hardware Course Overview and Requirements 1 2 MITSUBISHI ELECTRIC ...

Page 176: ...Device Edit 8 4 MITSUBISHI ELECTRIC ...

Page 190: ...Assigning DUT Variables to Function Blocks Data Unit Types DUT 10 10 MITSUBISHI ELECTRIC ...

Page 198: ...Array Example Single Dimension Array Arrays 11 8 MITSUBISHI ELECTRIC ...

Page 219: ...Sequential Function Chart SFC SFC Elements Training Manual GX IEC Developer 14 3 ...

Page 230: ...Structured Text Program Example IEC Structured Text 16 4 MITSUBISHI ELECTRIC ...

Page 278: ...PLC Components Glossary Appendix A 18 MITSUBISHI ELECTRIC ...

Page 283: ......