- 3.7 -

AFTER SETTING THE FABRIC TO BE PLOTTED

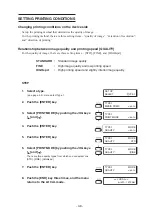

Correcting erroor of amount of feed depending on fabric [MEDIA COmp.]

The device plots an image on the fabric while feeding it forward little by little.

When the thickness of the fabric changes, the optimum feed rate changes accordingly. If this occurs,

the device may not plot a clear image (e.g., unwanted stripes may appear on the image). To correct

the fabric feed rate according to the fabric thickness, execute this function and make a printing test.

STEP

1.

Select a type.

(See page 3.4). Here, select [Type.1].

2.

Push the [ENTER] key.

3.

Push the [ENTER] key.

4.

Push the [ENTER] key.

Test printing for correction of the fabric feed rate starts.

Seven types of fabric correction patterns are plotted.

5.

Enter a correction value from the output pat-

tern.

Enter the correction value by pushing the JOG keys [ ] and

[ ].

If the printed pattern has a gap between lines: Select the

minus value.

If lines of the printed pattern overlap: Select the plus value.

6.

Push the [ENTER] key.

7.

Push the [END] key twice, and the menu re-

turns to the LOCAL mode.

•

[MEDIA COMP.] can be executed without performing [DATA CLEAR] even

after starting printing. (See page 3.22) Enter the local mode and then

change the correction value.

Optimum pattern

Overlap

Gap between lines

SET UP

SELECT

: TYPE.1

TYPE.1

MEDIA COMP.

< ent >

TYPE.1

PRINT START

: ent

PRINTING

PLEASE WAIT

TYPE.1

ADJUST

= 0

TYPE.1

PRINT START

: ent

<< LOCAL >>

width : 1272mm

Summary of Contents for TextileJet Tx2-1600 Series

Page 2: ......

Page 20: ...xvi...

Page 88: ...2 12...

Page 146: ...5 10...

Page 153: ......

Page 154: ...D200595 2 20 08032002...