Other settings

3-27

3

Conve

n

ie

nt

us

e

List of Settings

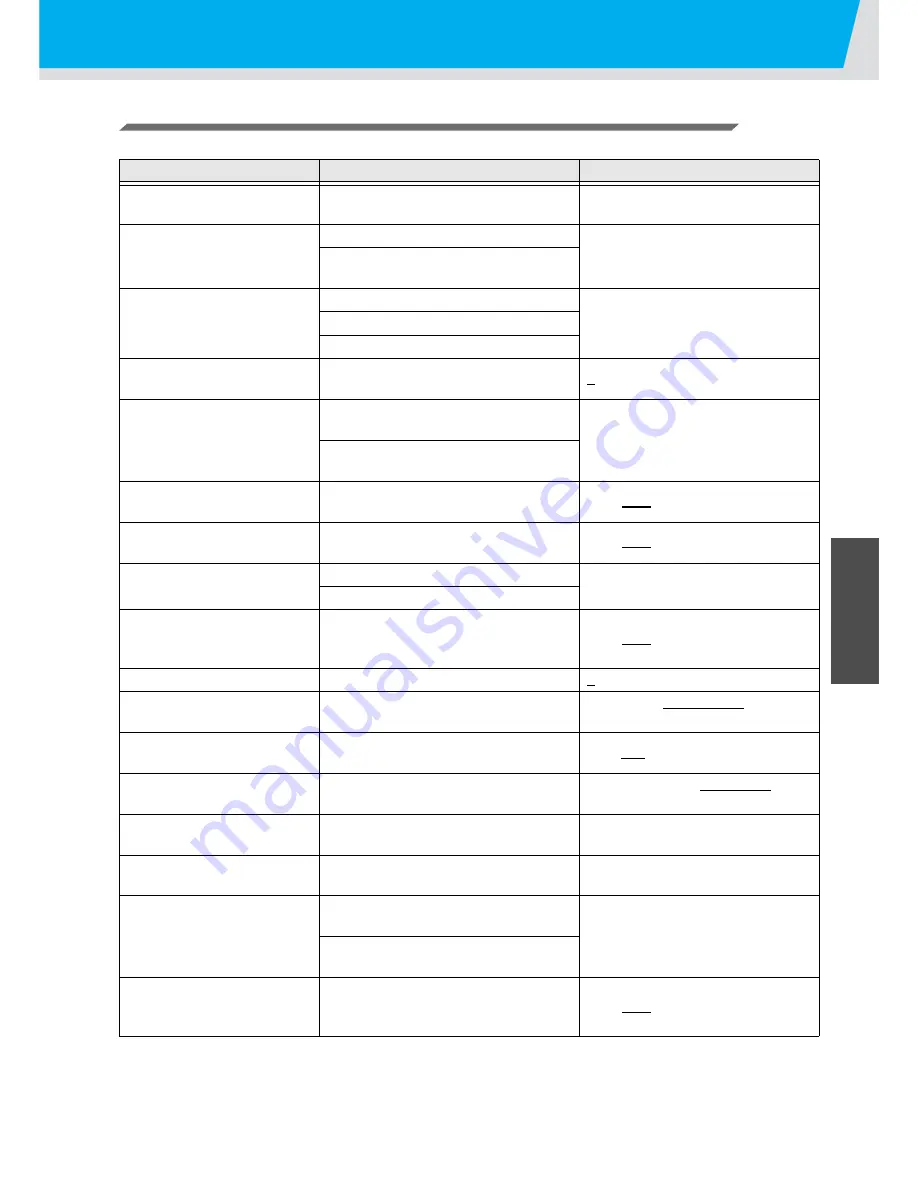

The underlined has been set when purchased.

Item

Outline

Set value

Setting of Media

compensation

Corrects the feeding rate of media

Refer to P.3-5

Setting of Heater

Setting Heater temperature

Refer to P.3-8

Setting Heater standby time and OFF

time

Setting of Printing mode

Setting Print quality

Refer to P.3-12

Setting Scanning direction

Setting Logical-seek

Setting of the number of ink

layers

Setting the number of layers in which

ink is to be applied.

1 ~ 9

Setting of Drying time

Setting the time for drying ink every

scanning.

Refer to P.3-16

Setting the time for drying ink after

the completion of printing.

Setting of Auto cut

Setting whether the media is cut

automatically or not after printing.

ON / OFF

Setting of Pre-feeding

Setting whether the media is carried

back and forth or not before printing.

ON / OFF

Setting of Margins

Setting a left margin on the media

Refer to P.3-17

Setting a right margin on the media

Setting of Color patterns

Setting whether color patterns are

printed at the right end of media or

not.

ON / OFF

Setting of Refreshing

Setting the refreshing level of head.

0 ~ 3

Setting of Adsorption

Setting the force adsorbing a media

STRONG / STANDARD /

Little WEAK / WEAK /OFF

Setting of Feeding speed

level

Changing the media feeding speed in

printing.

10 ~ 100 ~ 200%

Setting of Priority

Sets the priority of settings (host /

panel)

INDIVIDUALLY / ALL HOST /

ALL PANEL

Setting of Auto cleaning

Setting the auto head cleaning oper-

ation performed every printing.

Refer to P.3-20

Setting of In-printing clean-

ing

Setting the auto head cleaning oper-

ation performed during printing.

Refer to P.3-22

Setting of Media detection

Setting the media detecting opera-

tion.

Refer to P.3-24

Setting the detection conditions at

the cutting operation.

Setting of Feed Origin

Setting the media feeding direction to

LED pointer when changing the print-

ing origin position.

ON / OFF

Summary of Contents for JV33-130BS

Page 1: ...MIMAKI ENGINEERING CO LTD URL http www mimaki co jp D201887 16 ...

Page 7: ...vi ...

Page 32: ...1 16 ...

Page 107: ...3 51 Machine settings 3 Convenient use 7 Press the key 8 Press the key several times to end ...

Page 154: ...Setting Routine operations 4 36 8 Press the key several times to end ...

Page 164: ...4 46 ...

Page 187: ...6 11 Function Flowchart 6 Appendix To P 6 12 To P 6 18 To P 6 24 To P 6 25 To P 6 26 ...

Page 191: ...6 15 Function Flowchart 6 Appendix ...

Page 203: ...Function Flowchart 6 27 6 Appendix Error is displayed I n k REP L Re p o r t PR I NT I NG ...

Page 204: ...6 28 ...

Page 205: ...D201887 16 10022012 ...