- 3.10 -

Ink discharge way cleaning [Disway WASH]

When using Textile pigment ink (TPig), Reactive dye ink (Reac) or Acid dye ink (Acid), the ink

discharge way may become clogged by coagulated ink. It must be cleaned at regular intervals to

avoid clogging.

• Do not move the carriage out of the capping station by hand. Use the appro-

priate operation key to move the carriage.

Cleaning tool:

Ink-Cleaning Kit (SPC-0137:option)

STEP

1.

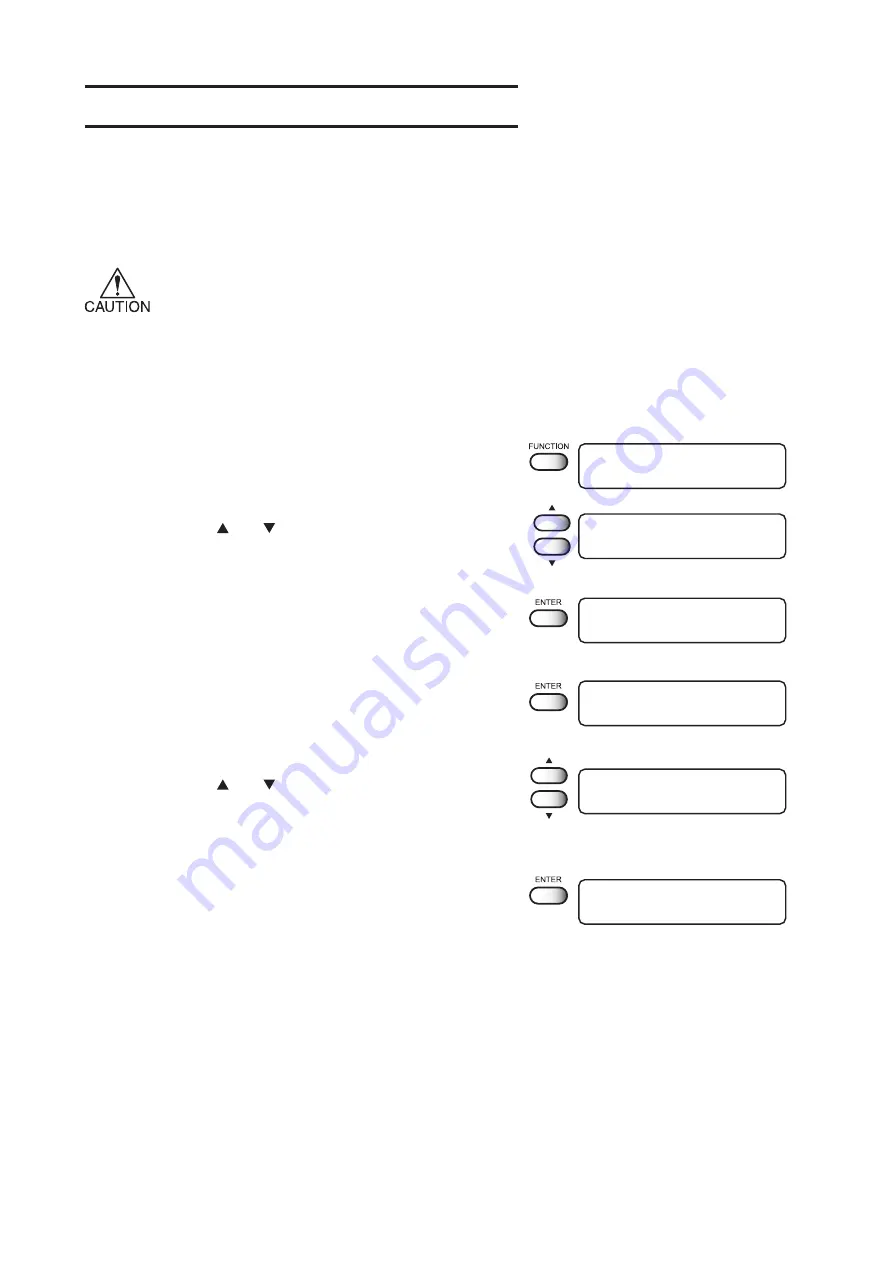

Press the [FUNCTION] key.

2.

Press the [ ] or [ ] key to select [MAINTENANCE].

3.

Press the [ENTER] key.

[STATION] is displayed.

4.

Press the [ENTER] key.

[CARRIAGE out] is displayed.

5.

Press the [ ] or [ ] key to select [Disway WASH].

6.

Press the [ENTER] key.

The carriage moves to the platen.

Air suction starts in cycles consisting of 5 seconds of suction

followed by 10 seconds of pause.

7.

Open the front cover.

FUNCTION

SET UP

< ENT >

FUNCTION

MAINTENANCE

< ENT >

MAINTENANCE

STATION

< ent >

STATION

MENT : CARRIAGEout

STATION

MENT : Disway WASH

STATION

COMPLETED

: ent

Summary of Contents for JV22-130

Page 2: ......

Page 34: ... 1 18 ...

Page 86: ... 4 14 ...

Page 120: ... A 6 ...

Page 125: ......

Page 126: ...PrintedinJapan D201031 MIMAKI ENGINEERING Co Ltd 2006 ...