Page 8

Accumass BW500

PL-565

About this

…

About the Accumass BW500

Note:

The ACCUMASS BW500 is to be used only in the manner outlined in this

instruction manual.

The ACCUMASS BW500 is a microprocessor based integrator designed for use with

Milltronics, or equivalent belt scales and weigh feeders. The speed and load signals

from the conveyor and scale, respectively, are processed to derive rate of material

flow, and totalization. The primary values of speed and load, and the derived values

of rate and total are available for display on the local LCD, or as output in the form of

analog mA, alarm relay and remote totalization.

BW500 supports Milltronics Dolphin Plus software and Modbus protocol on the two

RS-232 ports and the RS-485 port for communication to customer PLC or computer.

BW500 also supports Milltronics SmartLinx

®

for communication with popular

industrial communication systems.

Accumass BW500 features:

•

Reliable and robust user interface

✔

multi-field LCD display

✔

local keypad

•

Instrumentation I/O

✔

two remote totalizer contacts

✔

five programmable relays

✔

five programmable discrete inputs

✔

two programmable isolated mA input, for PID* control

✔

three programmable isolated mA output for rate, load, speed or PID* control

•

popular Windows

®

and Industrial communications

✔

two RS-232 ports

✔

one RS-485 port

•

individual port configuration for:

✔

Dolphin

✔

Modbus ASCII

✔

Modbus RTU

✔

Printer

✔

SmartLinx

®

compatible

•

Controls and operation functions

✔

load linearization

✔

auto zero

✔

PID* control

✔

batch control

✔

multispan operation

*PID control requires the optional mA I/O board.

Summary of Contents for ACCUMASS BW500

Page 1: ...ACCUMASS BW500 Instruction Manual PL 565 January 2001 CCUMASS BW500 33455650 Rev 1 2...

Page 6: ...Page 6 Accumass BW500 PL 565...

Page 12: ...Page 12 Accumass BW500 PL 565 Specifications...

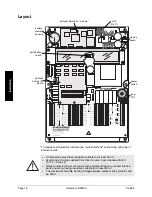

Page 28: ...Page 28 Accumass BW500 PL 565 Installation...

Page 88: ...Page 88 Accumass BW500 PL 565 Parameters...

Page 94: ...Page 94 Accumass BW500 PL 565 Operation...

Page 106: ...Page 106 Accumass BW500 PL 565 PID Control...

Page 110: ...Page 110 Accumass BW500 PL 565 Batching...

Page 112: ...Page 112 Accumass BW500 PL 565 Certification...