Bore diameter

determine and adjust boring tool.

Note

Boring operation

. . . . . . .

perform according to operating instructions for

boring tool used.

Cylinder bore

. . . . . . . . . . . . . . . . . . . . . . .

bevel at upper and lower edges of cylinder (see

drawing for dimensions).

operation

. . . . . . . . . . . . . . . . . . . . . . .

perform according to specified data.

The bore diameter

is the cylinder bore

diameter

minus the material which will be

removed by honing. The material removed by

honing should not exceed max. 0.05 mm. Select

repair stage diameter

according to engine

model and group code letter A, X,

(stamped

in block).

Maximum permissible wear for cylinder bores

Measuring range “a” (upper reversal point of 1st piston ring) in longitudinal

and/or transverse direction

0.2 mm

Standard and repair stage diameter

for cyl nder bores

Version

Cylinder

code

Standard

Repair stage

mm)

1 4, 5, 6

602, 603

603.970

Cylinder dia. D in mm

Cylinder dia. D in mm

87.000

87.006

89.000

89.006

over

87.006

87.012

over

89.006

89.012

over

87.012

87.018

over

89.012

89.018

87.700

87.706

89.700

89.706

87.706

87.712

89.706

89.712

87.712

87.718

89.712

89.718

Does not app y 0

f engines

cylinder sleeves. Cylinder sleeves must be replaced when the wear

IS

reached.

Machining tolerances

Permissible out-of-round and conicity of cylinder bore

0.07 mm

Permissible roughness of cylinder bore

0.003 0.006 mm

Permissible waviness of cylinder bore

50 of roughness

l-ioning angle

45”

Roughness of block parting surface

0.006 0.016 mm

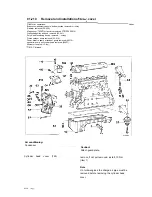

Chamfer of cylinder bores

refer to figure

Summary of Contents for 602

Page 1: ...Mercedes Benz Mercedes Benz of North America Inc Montvale NJ 07645 ...

Page 5: ...General technical data 00 ...

Page 15: ...Crankcase and Cylinder Head 01 ...

Page 22: ......

Page 33: ......

Page 89: ......

Page 140: ......

Page 191: ...This page int ntiowally left blank 03 10 32113 ...

Page 227: ...ine Timing Valvstr ...

Page 282: ...Special tool f 05 10 310 5 ...

Page 301: ...ystern Air r Turbocharger 09 ...