Page 19

Speed Level Seres - Servce & Parts Manual

January 2019

Secton 5 - Hydraulc System

Hydraulic Fluid

Handling Precautions

PERSONS IN REGULAR CONTACT WITH MINERAL-BASED HYDRAULIC

FLUID NEED TO BE AWARE OF THE IMPORTANCE OF THOROUGH

HYGIENE AND THE PROPER METHODS FOR HANDLING MINERAL OILS,

IN ORDER TO AVOID POTENTIAL HAZARDS TO HEALTH������

IF MINERAL-BASED HYDRAULIC FLUID IS SPLASHED INTO THE

EYES, IT MUST BE WASHED OUT THOROUGHLY USING ABUNDANT

QUANTITIES OF WATER������ SEEK MEDICAL ATTENTION IF IRRITATION

PERSISTS������

HYDRAULIC FLUID UNDER PRESSURE CAN PENETRATE AND

BURN SKIN, DAMAGE EYES, AND MAY CAUSE SERIOUS INJURY OR

BLINDNESS������

FLUID LEAKS UNDER PRESSURE MAY NOT ALWAYS BE VISIBLE������

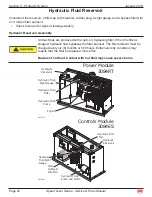

Fluid Recommendations

MEC recommends the use of

Mobile Fluid DTE 10

,

DTE 13 M

or

AW32

hydraulic fluid.

Do not substitute with lower grade fluids as pump damage may result.

System Flushing Procedure

With platform fully down, drain hydraulic fluid from hydraulic reservoir into a clean, empty

container.

When the hydraulic reservoir is empty, remove suction strainer and hoses.

Remove the bypass filter and hose.

Flush the hoses with clean hydraulic fluid.

Discard old bypass filter element and replace.

Flush out the reservoir with hoses removed from the hydraulic reservoir.

Reinstall all hoses removed in the previous steps.

Fill hydraulic reservoir with filtered, fresh hydraulic fluid (refer to Lubrication Chart).

Loosen output hose fittings at pump to flood with hydraulic fluid. Tighten fittings.

Start up the machine. Briefly operate all functions. Two or three lift cycles may be necessary to

purge all air from lift cylinder(s).

When the above procedures have been completed, fill hydraulic reservoir to full mark on sight

gauge.

Check all leaks and correct as necessary. Machine is now ready to be placed back in operation.

Note:

Avoid mixing petroleum and synthetic base fluids. It is not advisable to mix fluids of different

brands or types, except as recommended.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.