Page 25

Speed Level Seres - Servce & Parts Manual

January 2019

Secton 5 - Hydraulc System

Hydraulic Manifold

Note:

Refer to Parts Section 15.

Tag all components as they are removed to aid in reassembly.

•

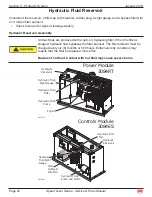

Hydraulic Manifold Removal

Disconnect the negative battery terminal.

Tag and disconnect the solenoid valve leads.

Tag and disconnect hydraulic hoses, and IMMEDIATELY cap the openings to prevent

contamination.

Remove the bolts that hold the manifold to the mounting bracket.

Remove the manifold block.

Disassembly

Remove coils from solenoid valves.

Mark and remove valves.

Mark and remove fittings, plugs, springs, balls, and orifices.

Cleaning And Inspection

Wash the manifold in cleaning solvent to remove built-up contaminants, then blow out all

passages with clean compressed air.

Inspect the manifold for cracks, thread damage and scoring where O-rings seal against internal

and external surfaces.

Wash and dry each component and check for thread damage, torn or cracked O-rings, and

proper operation.

Replace defective parts and O-rings.

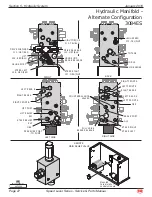

Assembly

Note:

Lubricate all O-rings before installation to prevent damage to the O-ring. Seat balls in manifold

block by lightly tapping on the ball with a brass drift punch.

Install fittings, plugs, springs, balls, and orifices. Use one drop of Loctite #424 or equivalent

thread locker on each screw-in orifice.

Install valves.

Installation

Attach manifold assembly to mounting plate with mounting bolts.

Connect solenoid leads (as previously tagged).

Connect hydraulic hoses (as previously tagged). Be certain to tighten hoses.

Connect the battery.

Operate each hydraulic function and check for proper operation and leaks.

Adjust valve pressures.

1.

2.

3.

4.

5.

1.

2.

3.

1.

2.

3.

4.

1.

2.

1.

2.

3.

4.

5.

6.