Page 115

Speed Level Seres - Servce & Parts Manual

January 2019

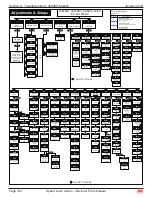

Secton 8 - Troubleshootng - 3084RT Models

Problem

Possible Cause

Remedy/Solution

Platform will

not lower or

lowers slowly

Maintenance lock in maintenance position

Return maintenance lock to the stowed position

Lowering valve not energized

Check wiring to lowering valve located on Lift Cylinder

Lowering valve not shifting

Clean debris, check for damage, replace

Lowering orifice/s plugged

Clean orifice/s located inside hose fitting on lift cylinder

System interruption

Check HELP messages using EZ-Cal

Lowers but

not completely

Down valve on lift cylinder inoperative

Check lift valve coil

Emergency

lowering not

working

Lowering valve not shifting

Clean debris, check for damage, replace

Lowering orifice plugged

Clean orifice/s located inside hose fitting on the lift cylinder

E-down battery discharged

Charge, check charge diode & connections

Valve coil failed on cylinder

Test (6-8 ohms), replace

Drive

No drive

function

Lift/Drive select switch not in Drive position

or not operational

Select Drive position (upper control box), Check switch

Check switch position from GP400 with EZ-Cal (see EZ-Cal ID# 2b-2)

DLD

Drive valve not shifting (SVD1)

Check connections at valve

Check Drive Valve for contamination

Check Drive output from GP400 (See EZ-Cal chart ID# 2b-4 & 2b-5

also 2f1-4 & 2f-15)

Proportional Valve not shifting (SP1)

Check connections at valve

Check Proportional valve for contamination

Check proportional output from GP400 (see EZ-Cal ID# 2f-9 & 2b-3)

Drive system shut down (interlock)

Check HELP and MODE message on EZ-Cal

No drive

elevated

Unit out of level

Lower and operate Auto-level

System Interruption (interlock)

Check HELP messages using EZ-Cal

Slow drive

with platform

stowed

High torque enabled

Check Speed/Torque switch on upper controls

Malfunctioning rear wheel bypass valve

Located on rear wheel motors only

Check electrical by disconnecting valves

Check function by replacing valves

Wheel motors not functioning correctly

Inspect wheel motors for excessive bypass

Poor

gradeability

or drive

performance

High or mid speed enabled

Check Speed/Torque switch on upper controls

Batteries discharged

Check battery voltage with multi-meter or EZ-Cal

Clean, service, charge batteries

Wheel motors not functioning correctly

Inspect wheel motors for excessive bypass

Malfunctioning rear wheel bypass valve

Located on rear wheels only

Check electrical by disconnecting valves

Check function by replacing valves

Malfunctioning series parallel valves

Located on top of main hydraulic manifold PD1, PD2 & PD3

Remove and inspect

Incorrectly adjusted or worn hydraulic

pump

See Hydraulics section for pump adjustment

Inspect or replace pump

Drive in one

direction only

Drive valve SVD1 not energized in one

direction

Check 12 volts to appropriate coil

Check coil

Check valve function

Counterbalance valve CBV1 or CBV2 not

functioning correctly

Swap counterbalance valves to see if functioning direction changes

No output from GP400

Check switch position output from GP400 (see EZ-Cal ID# 4f-7

– FWD or 2f-9 – Reverse)