Page 151

Speed Level Seres - Servce & Parts Manual

January 2019

Secton 9 - Troubleshootng - 3084ES Models

No drive elevated

Unit out of level

Lower and re-position the machine.

Batteries discharged

Will receive 4-4 or 7-7 flash on GP400. Clean, service

and charge batteries.

Battery charger may not operate if battery voltage

drops below 20 volts

Slow drive with

platform in

stowed position

System interlock

Check HELP messages using EZ-Cal

High torque enabled

Check Speed/Torque Switch at platform controls

Elevation sensor out of calibration

Use EZ-Cal to monitor platform state of elevation. See

Diagnostic chart I.D. 2a13 for elevated status and 2e1

for platform % of elevation input. Failure of the angle

transducer will trigger a fault code.

Malfunctioning rear wheel bypass

valve

Located on rear wheel motors only. Check by

replacing valves.

Wheel motor/s not functioning

correctly

Inspect wheel motors for excessive bypass

Poor gradability

performance

High or Mid Speed enabled

Check Speed/Torque Switch

Batteries discharged

Will receive 4-4 or 7-7 flash on GP400, Clean, service

and charge batteries.

Battery charger may not operate if battery voltage

drops below 20 volts

Wheel motor/s not functioning

correctly

Inspect wheel motors for excessive bypass

Malfunctioning Rear wheel bypass

valve

Located on rear wheel motors only. Check electrical

by disconnecting valves or function by replacing

valves

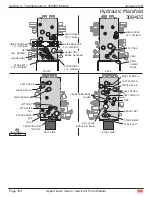

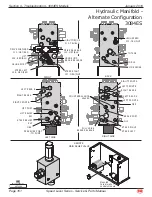

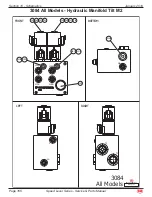

Malfunctioning Series/Parallel Valves Located on top of main hydraulic Manifold

Worn hydraulic pump

Check with flow meter or replace pump

Drive in one

direction only

Drive Valve SVD1 not energizing in

one direction

Check 12 volts to appropriate coil, check coil, check

valve function

Counterbalance Valve CBV1 or

CBV2 malfunction

Swap counterbalance valves to see if functioning

direction changes.

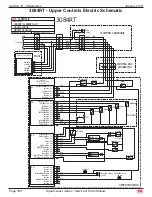

No output from GP400

Scan using EZ-Cal and troubleshooting charts. EZ-Cal

chart I.D 4f-7 - Fwd or 2f-9 - Reverse

No Low Speed

(high torque

mode)

Speed/torque selector switch

inoperative

Check continuity of Speed/Torque switch in platform

control box

Valve SV3 not functioning

Check for 12 volts and ground to valve check for faulty

valve spool

EP1 poppet valve not functioning

Check or replace valve

No Mid Speed

SV3 or SV4 powered and/or shifted

These valves should not have 12 volts, in mid-speed,

check valve function

Speed/torque selector switch

malfunction

Check continuity through switch

No High Speed

Speed/torque selector switch

inoperative

Check continuity of Speed/Torque switch in platform

control box

Valve SV4 not functioning

Check voltage and ground to valve check for faulty

valve spool

EP2 poppet valve not functioning

Check or replace valve

No brake

effectiveness

Brake Orifice OD-1 obstructed

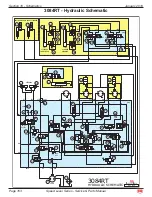

Remove, clean orifice. See hydraulic diagram for

location in manifold.

Brake discs worn past service limit

Replace brake discs located inside rear wheel motors.