TPM 083/12

12

Park Allé 366, DK-2605 Brondby

Telefon 70 20 19 11; E-mail:[email protected]

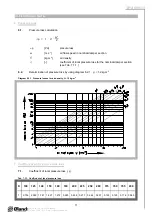

8. Noise data

8.1.

Level of acoustic output corrected with filter A.

L

WA

[dB(A)] level of acoustic output corrected with filter A

L

W1

[dB]

level of acoustic output L

W1

related to the 1 m

2

section (see Tab. 8.3.1.)

S

[m

2

]

effective area of the damper

K

A

[dB]

correction to the weight filter A (see Tab. 8.3.2.)

L

WA

= L

W1

+ 10 log(S) + K

A

8.2.

Level of acoustic output in octave ranges.

L

Woct

[dB]

spectrum of acoustic output in octave range

L

W1

[dB]

level of acoustic output L

W1

related to the 1 m

2

section (see Tab. 8.3.1.)

S

[m

2

]

effective area of the damper

L

rel

[dB]

relative level expressing the shape of the spectrum (see Tab. 8.3.3.)

L

Woct

= L

W1

+ 10 log(S) + L

rel

8.3.

Table of acoustics values

Tab. 8.3.1. Level of acoustic output L

W1

related to the 1 m

2

section

[-]

w [m.s

-1

]

0,1

0,2

0,3

0,4

0,6

0,8

1

1,5

2

2,5

3

3,5

2

9,0

11,5 14,7 16,9 20,1

22,3

24,1

27,2

29,4

31,2

32,6

33,8

3

16,7 22,1 25,3 27,5 30,7

32,9

34,6

37,8

40,0

41,7

43,2

44,4

4

24,2 29,6 32,8 35,0 38,1

40,4

42,1

45,3

47,5

49,2

50,7

51,9

5

30,0 35,4 38,6 40,8 44,0

46,2

47,9

51,1

53,3

55,1

56,5

57,7

6

34,8 40,2 43,3 45,6 48,7

51,0

52,7

55,8

58,1

59,8

61,2

62,4

7

38,8 44,2 47,3 49,6 52,7

55,0

56,7

59,9

62,1

63,8

65,2

66,4

8

42,3 47,7 50,8 53,1 56,2

58,4

60,2

63,3

65,6

67,3

68,7

69,9

9

45,4 50,7 53,9 56,1 59,3

61,5

63,3

66,4

68,6

70,4

71,8

73,0

10

48,1 53,5 56,6 58,9 62,0

64,3

66,0

69,1

71,4

73,1

74,5

75,7

11

50,6 56,0 59,1 61,4 64,5

66,7

68,5

71,6

73,9

75,6

77,0

78,2

12

52,8 58,2 61,4 63,6 66,8

69,0

70,7

73,9

76,1

77,9

79,3

80,5