6

7

8

Replacing cylinder liners

114

Installing cylinder liners

Fig. 6

Insert dry new O-rings for the lower seal (144x4)

into the crankcase.

Fig. 7

Insert new O-rings for the upper seal (138x2) into

the grooves on the cylinder liner.

Do not overstretch the O-rings.

Fig. 8

Apply thin coat of engine oil to cylinder liner in the

area of the upper and lower O-ring.

Apply thin coat of engine oil to lower O-rings in the

crankcase.

Insert cylinder liners into crankcase and push them

down by hand.

Place clean metal plate on liner and exert uniform

downward pressure until the liner is seated in the

crankcase recess.

If a perceptible resistance can be felt in this oper-

ation, the O-rings are no longer in their proper

place.

Reposition O-rings and insert cylinder liner again.

Note:

No grease or sealing agents of any kind

must be used for installing cylinder liners and

O-rings.

Note:

After fitting the cylinderliners ensure that the

O-rings are in the correct position by checking

the liner protrusion with special tool. Use

special tool, see page 132 as follows:

Position press-on measuring plate (1) with

turned collar facing the liner using 2 fitting

sleeves to centre plate.

Tighten 4 bolts (2) (improvised: collar bolt

51.90020-0270, length shortened to 90 mm)

on the press-on measuring plate in stages and

crosswise to 40 Nm.

Set dial gauge combination above press-on

plate to “0” under preload relative to the crank-

case.

Measure cylinder liner protrusion at least at

four points.

3574

3575

3576

Summary of Contents for D 2866 LE 401

Page 1: ......

Page 17: ...Engine views D 2866 LE401 16...

Page 18: ...Engine views D 2866 LE401 17...

Page 19: ...Cross section of engine 18...

Page 20: ...Longitudinal section 19...

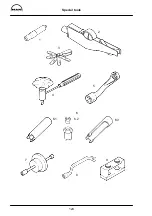

Page 124: ...123 Special tools...

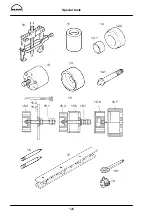

Page 125: ...Special tools 124 2 3 4 5 6 7 9 1 8 6 1 6 2 6 3...

Page 129: ...Special tools 128 21 22 23 25 25 2 24 25 1 26 27 1 27 2 27 20 1 19 2 19 1 20 2 19 20...

Page 131: ...Special tools 130 29 28 30...

Page 138: ......