12

13

14

15

Removing and installing vibration damper,

changing front crankshaft seal

61

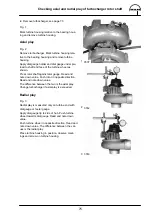

Installing vibration damper

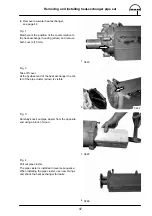

Fig. 12

Place vibration damper on two guide pins (M16 x

1.5). Ensure that the position of the graduated disc

relative to the crankshaft is correct.

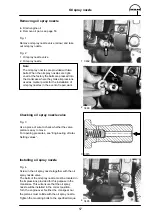

Fig. 13

Tighten mounting bolts (24 mm) to specified

torque.

Note:

Owing to the high tightening torque a rein-

forced socket in conjunction with a 1/2” tool

is required.

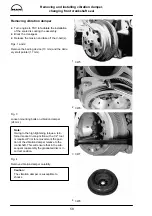

Fig. 14

Screw on delivery start indicator and

V-belt pulleys.

Fit and tension V-belts (see page 118).

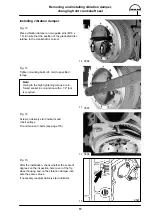

Fig. 15

After the installation, check whether the scale of

degrees on the inspection hole cover of the fly-

wheel housing and on the vibration damper indi-

cate the same values.

If necessary readjust delivery start indicator.

3584

3587

3484

2591

Summary of Contents for D 2866 LE 401

Page 1: ......

Page 17: ...Engine views D 2866 LE401 16...

Page 18: ...Engine views D 2866 LE401 17...

Page 19: ...Cross section of engine 18...

Page 20: ...Longitudinal section 19...

Page 124: ...123 Special tools...

Page 125: ...Special tools 124 2 3 4 5 6 7 9 1 8 6 1 6 2 6 3...

Page 129: ...Special tools 128 21 22 23 25 25 2 24 25 1 26 27 1 27 2 27 20 1 19 2 19 1 20 2 19 20...

Page 131: ...Special tools 130 29 28 30...

Page 138: ......