1

2

3

4

V-belts

117

Checking condition

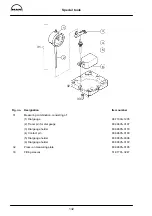

Fig. 1

D

Check V-belts for cracks, oiling, overheating

and wear.

D

Change damaged V-belts.

Checking tension

Figs. 2 and 3

Use belt tension indicator to check V-belt tension.

D

Lower the gauge arm

À

in the scale.

D

Position the tension indicator in the centre of

the belt between the two pulleys so that the

edge of the stop face

Á

locates against the side

of the belt.

D

Slowly depress the pressure pad

Â

vertically

downwards until the spring disengages with an

audible click; the gauge arm moves upwards.

A false reading will be obtained if you continue to

apply pressure after the spring has disengaged.

Fig. 4

Taking tension reading

D

The tension is shown where the top of the

gauge arm (1 in picture 2) intersects the kg

scale.

D

Ensure that the gauge arm does not move be-

fore you take the reading.

If the reading does not correspond with the speci-

fied value, the V-belt tension must be corrected.

2642

1

2905

2

3

2906

Tensioning forces as per kg scale on

the indicator

V-belt

for newly fitted

assembly

for mainte-

nance af-

width

after as-

sembly

after a

running

time of

10 min.

nance af

ter prolon-

ged pe-

riods of

operation

B 12,5

50-55

45-50

35

C 13

50-55

40-45

35

2/3VX

90-100

70-80

60

Summary of Contents for D 2866 LE 401

Page 1: ......

Page 17: ...Engine views D 2866 LE401 16...

Page 18: ...Engine views D 2866 LE401 17...

Page 19: ...Cross section of engine 18...

Page 20: ...Longitudinal section 19...

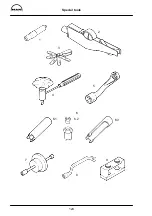

Page 124: ...123 Special tools...

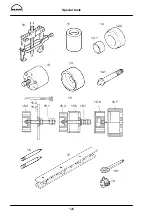

Page 125: ...Special tools 124 2 3 4 5 6 7 9 1 8 6 1 6 2 6 3...

Page 129: ...Special tools 128 21 22 23 25 25 2 24 25 1 26 27 1 27 2 27 20 1 19 2 19 1 20 2 19 20...

Page 131: ...Special tools 130 29 28 30...

Page 138: ......