1

2

3

4

Oil spray nozzle

57

Removing oil spray nozzle

D

Drain engine oil

D

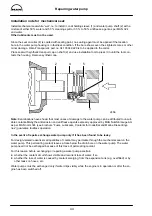

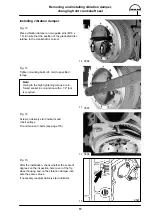

Fig. 1

Remove oil spray nozzle valve (arrow) and take

out oil spray nozzle.

Fig. 2

1 Oil spray nozzle valve

2 Oil spray nozzle

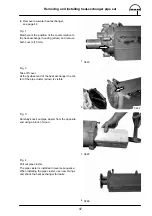

Note:

The oil spray nozzles are provided with two

balls. When the oil spray nozzles are tight-

ened at the factory the balls are pressed into

the crankcase where they make impressions

used as marker points for the installation of

oil spray nozzles in the event of repair work.

Checking oil spray nozzle valve

Fig. 3

Use a piece of wire to check whether the valve

piston is easy to move.

For opening pressures, see ”Engineering

S

Data

S

Setting values”.

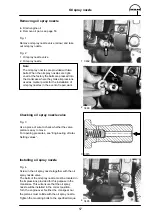

Installing oil spray nozzle

Fig. 4

Screw in the oil spray nozzle together with the oil

spray nozzle valve.

The balls of the oil spray nozzle must be located in

the impressions provided for this purpose in the

crankcase. This will ensure that the oil spray

nozzle will be installed in the correct position.

Turn the engine over. Neither the crankgear nor

the pistons must collide with the oil spray nozzle.

Tighten the mounting bolts to the specified torque.

3462

3463

2

1

3673

3465

Summary of Contents for D 2866 LE 401

Page 1: ......

Page 17: ...Engine views D 2866 LE401 16...

Page 18: ...Engine views D 2866 LE401 17...

Page 19: ...Cross section of engine 18...

Page 20: ...Longitudinal section 19...

Page 124: ...123 Special tools...

Page 125: ...Special tools 124 2 3 4 5 6 7 9 1 8 6 1 6 2 6 3...

Page 129: ...Special tools 128 21 22 23 25 25 2 24 25 1 26 27 1 27 2 27 20 1 19 2 19 1 20 2 19 20...

Page 131: ...Special tools 130 29 28 30...

Page 138: ......