1

2

3

4

Removing and installing flywheel,

replacing gear ring

62

Removing flywheel

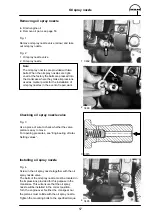

Fig. 1

Loosen mounting bolts (24 mm), securing the en-

gine against turning if necessary.

Note:

Owing to the high initial torque a reinforced

socket (for machine screws) in connection

with a 1/2” tool is required.

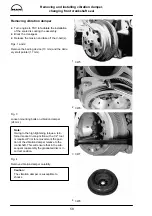

Fig. 2

Remove two bolts facing each other and replace

them by two guide pins (special tool, see

page 127, item. 16).

Remove all bolts.

Fig. 3

Pull off flywheel using a flat metal bar and two

bolts M12 x 1.5. Do not tilt it so that it jams.

Caution:

The flywheel is heavy.

Use lifting gear.

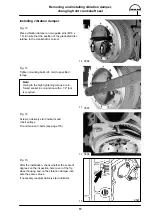

Installing flywheel

Fig. 4

Screw in guide mandrels

(special tool, see page 127, item 16).

Apply sealing agent ”Antipor 46” to the inside of

the flywheel.

Place guide mandrels on the flywheel, ensuring

that the centering mandrel (arrow) fits correctly into

the bore in the flywheel. Push on flywheel until it

stops.

3466

3675

3468

3676

Summary of Contents for D 2866 LE 401

Page 1: ......

Page 17: ...Engine views D 2866 LE401 16...

Page 18: ...Engine views D 2866 LE401 17...

Page 19: ...Cross section of engine 18...

Page 20: ...Longitudinal section 19...

Page 124: ...123 Special tools...

Page 125: ...Special tools 124 2 3 4 5 6 7 9 1 8 6 1 6 2 6 3...

Page 129: ...Special tools 128 21 22 23 25 25 2 24 25 1 26 27 1 27 2 27 20 1 19 2 19 1 20 2 19 20...

Page 131: ...Special tools 130 29 28 30...

Page 138: ......