REPAIR INSTRUCTIONS, PART 3

Page 465

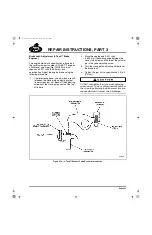

Engine Operational Check

1. Remove all tools from the engine

compartment.

2. Connect the battery cables (negative cable

last).

3. Clear the work area of debris and personnel.

The following step is important to ensure

adequate break-in for all new parts — camshaft,

lifters, crankshaft, bearings, etc. — at initial

startup of the engine.

4. Start the engine and immediately increase

the speed to 1200 rpm. Operate the engine

in the range of 1200–1600 rpm for

15 minutes. DO NOT allow the engine to

drop to idle speed until the 15 minute

break-in period at 1200–1600 rpm has been

completed. During the break-in period,

check for leaks and monitor gauges for

satisfactory oil pressure, etc.

5. After the break-in is complete, shut down the

engine. Check the fluid levels and fill to

capacity before restarting the engine.

6. Refer to the “Rebuilt Engine Run-In

Procedures” for checks to ensure proper

engine operation before releasing the

vehicle for service.

REBUILT ENGINE RUN-IN

PROCEDURES

General Instructions

The durability and service life of a rebuilt engine

is directly related to its initial run-in following

overhaul. After a complete overhaul or any major

repair job involving installation of piston rings,

pistons, cylinder sleeves or bearings, the engine

must be run-in prior to release for service.

Run-in procedures vary depending on method

used (i.e., engine dynamometer, chassis

dynamometer or highway run-in). Regardless of

method, however, always properly prepare the

engine before starting it for the first time.

Run-In Check

Install any additional instrumentation needed for

the run-in method selected.

The operator should be familiar with the correct,

established procedure for checking chassis

power

before

using the chassis dynamometer

method for run-in (refer to applicable chassis

dynamometer operation procedures).

The operator must be observant throughout the

entire run-in procedure, in order to detect any

problems that develop. Constantly monitor the

instrumentation displaying functions of the engine

and support systems, and record all readings.

If, during run-in, the engine develops any of the

following abnormal running characteristics, shut it

down immediately. Investigate and correct the

problem before continuing the run-in procedure.

Always investigate the following conditions:

앫

Unusual noises such as knocking, scraping,

etc.

앫

A significant drop in engine oil pressure

앫

A significant rise in coolant temperature,

exceeding 240

°

F (116

°

C)

앫

A significant rise in oil temperature that

exceeds 240

°

F (116

°

C)

앫

An exhaust temperature that exceeds

maximum acceptable limits for the specific

engine involved, as measured by a

pyrometer (if vehicle is equipped with a

pyrometer)

앫

Any oil, coolant or air inlet system leaks

CYLINDER HEAD RETORQUING

After completing the run-in procedure, in

sequence, back off each cylinder head capscrew

individually until free. Then retorque the same

capscrew to 205 lb-ft (278 N

폷

m).

5-111.bk Page 465 Monday, July 10, 2006 2:26 PM

Summary of Contents for ASET AC

Page 6: ...TABLE OF CONTENTS Page iii TABLE OF CONTENTS 5 111 bk Page iii Monday July 10 2006 2 26 PM...

Page 14: ...INTRODUCTION Page 1 INTRODUCTION 5 111 bk Page 1 Monday July 10 2006 2 26 PM...

Page 23: ...Page 10 NOTES 5 111 bk Page 10 Monday July 10 2006 2 26 PM...

Page 96: ...COMPONENT LOCATOR Page 83 COMPONENT LOCATOR 5 111 bk Page 83 Monday July 10 2006 2 26 PM...

Page 99: ...Page 86 NOTES 5 111 bk Page 86 Monday July 10 2006 2 26 PM...

Page 100: ...TROUBLESHOOTING Page 87 TROUBLESHOOTING 5 111 bk Page 87 Monday July 10 2006 2 26 PM...

Page 140: ...MAINTENANCE Page 127 MAINTENANCE 5 111 bk Page 127 Monday July 10 2006 2 26 PM...

Page 153: ...Page 140 NOTES 5 111 bk Page 140 Monday July 10 2006 2 26 PM...

Page 383: ...Page 370 NOTES 5 111 bk Page 370 Monday July 10 2006 2 26 PM...

Page 479: ...Page 466 NOTES 5 111 bk Page 466 Monday July 10 2006 2 26 PM...

Page 480: ...SPECIFICATIONS Page 467 SPECIFICATIONS 5 111 bk Page 467 Monday July 10 2006 2 26 PM...

Page 505: ...Page 492 NOTES 5 111 bk Page 492 Monday July 10 2006 2 26 PM...

Page 513: ...Page 500 NOTES 5 111 bk Page 500 Monday July 10 2006 2 26 PM...

Page 519: ...Page 506 NOTES 5 111 bk Page 506 Monday July 10 2006 2 26 PM...

Page 520: ...APPENDIX Page 507 APPENDIX 5 111 bk Page 507 Monday July 10 2006 2 26 PM...

Page 528: ...INDEX Page 515 INDEX Index fm Page 515 Monday July 10 2006 2 48 PM...

Page 535: ...Page 522 NOTES Index fm Page 522 Monday July 10 2006 2 48 PM...