LNC-T800

CNC Group Instruction

4

LNC Technology Co., Ltd.

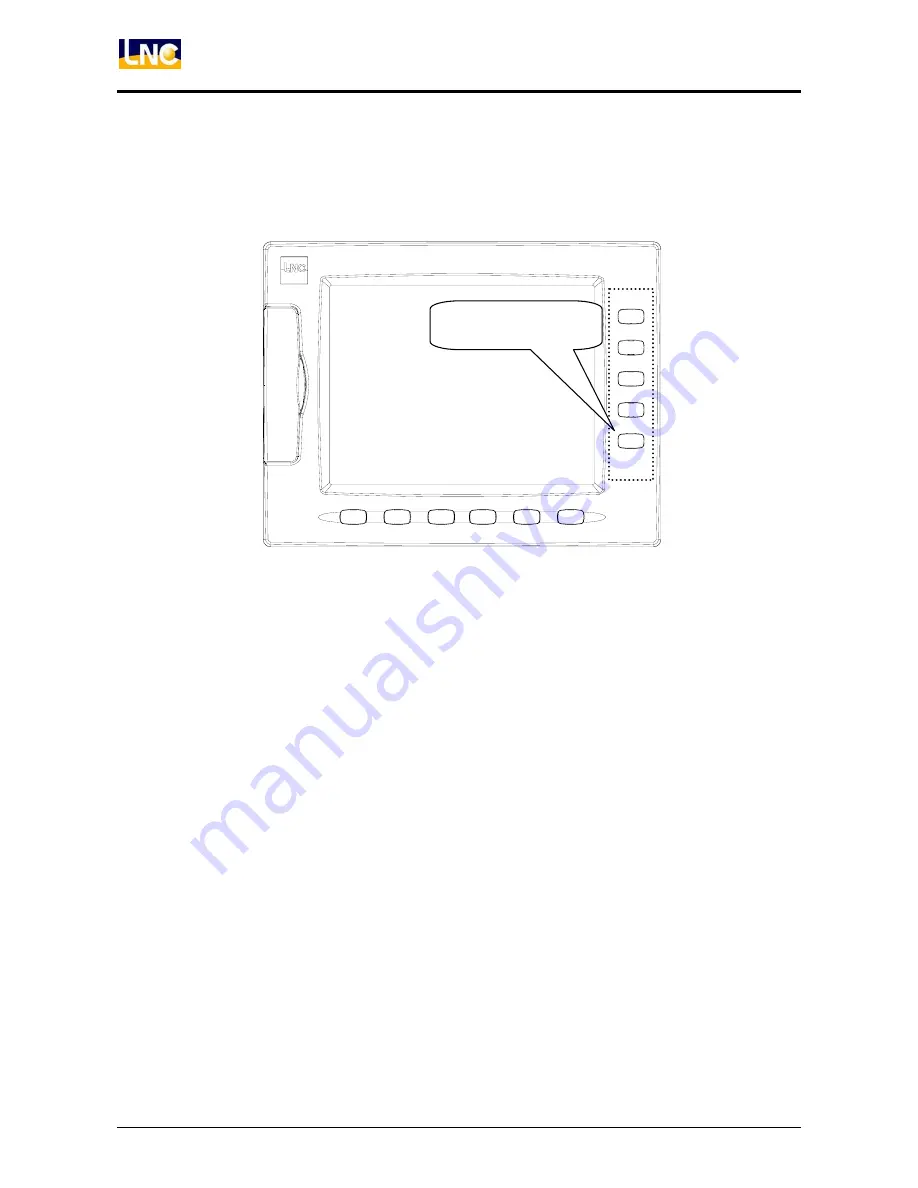

(2). Minor function button:

After selecting the major function buttons, minor function contents will be displayed on the right side of

the monitor. Click the corresponding minor function button to make selection.

Figure 1.2-2 5 minor function buttons on the right side of the monitor

寶元科技

Minor function buttons

Summary of Contents for LNC-T800

Page 2: ......